Help document

Copyright © RATA Co. 2021-2025

1.

Table of Contents

3.1.1.

Read or Create CAD Files

According to Plant BOM

3.1.2. Visualize The Family Tree

3.1.3.

Create Family Tree Chart in

Excel

3.1.4. Definition of Processes

3.1.5.

Creation of Process Sheet

Drawings

3.1.6.

Validation of Drawings by

Tracking the Changes in Process Plan

4.1.1.1. Parent Children Excel Sheet Format

6.1.1. Import From Catia BiW Fastening

6.1.3. Process Excel File Format

6.1.3.4. Resolving Panel Ambiguity

6.2.1.1. Create BiW Fastening Options

6.3. Generate Drawing Sheet(s)

6.3.1.

Process Sheet Creation Dialogue

Box

6.3.1.3. Selection of stations

6.3.1.4. Selection by Panel (Pairs)

6.3.1.6. Selection by Process ID

6.3.1.7. Sheet Template Selection

6.3.1.10. Create Drawing Button

6.3.3.

Partial View Extent Adjustment

in CATIA

6.3.4.

Partial View Extent Adjustment

in Crop Window

6.6.3. Define and Edit a Standard

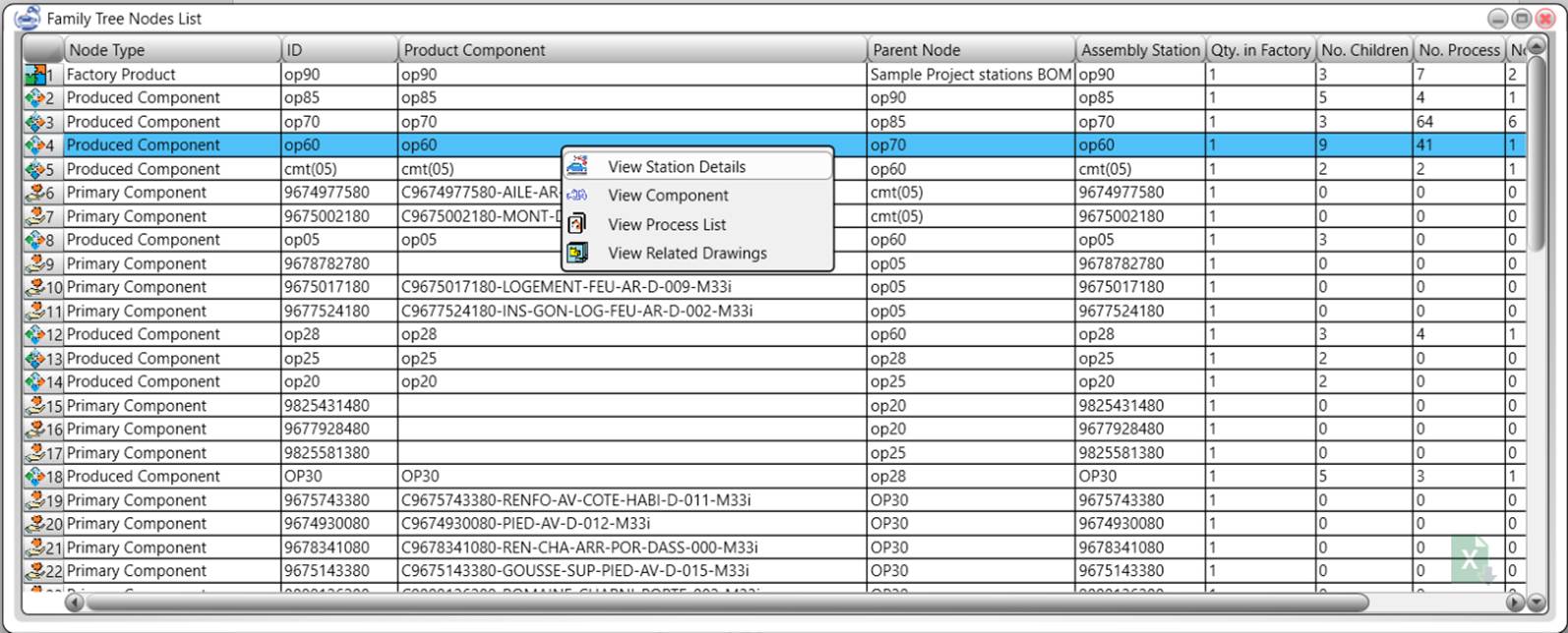

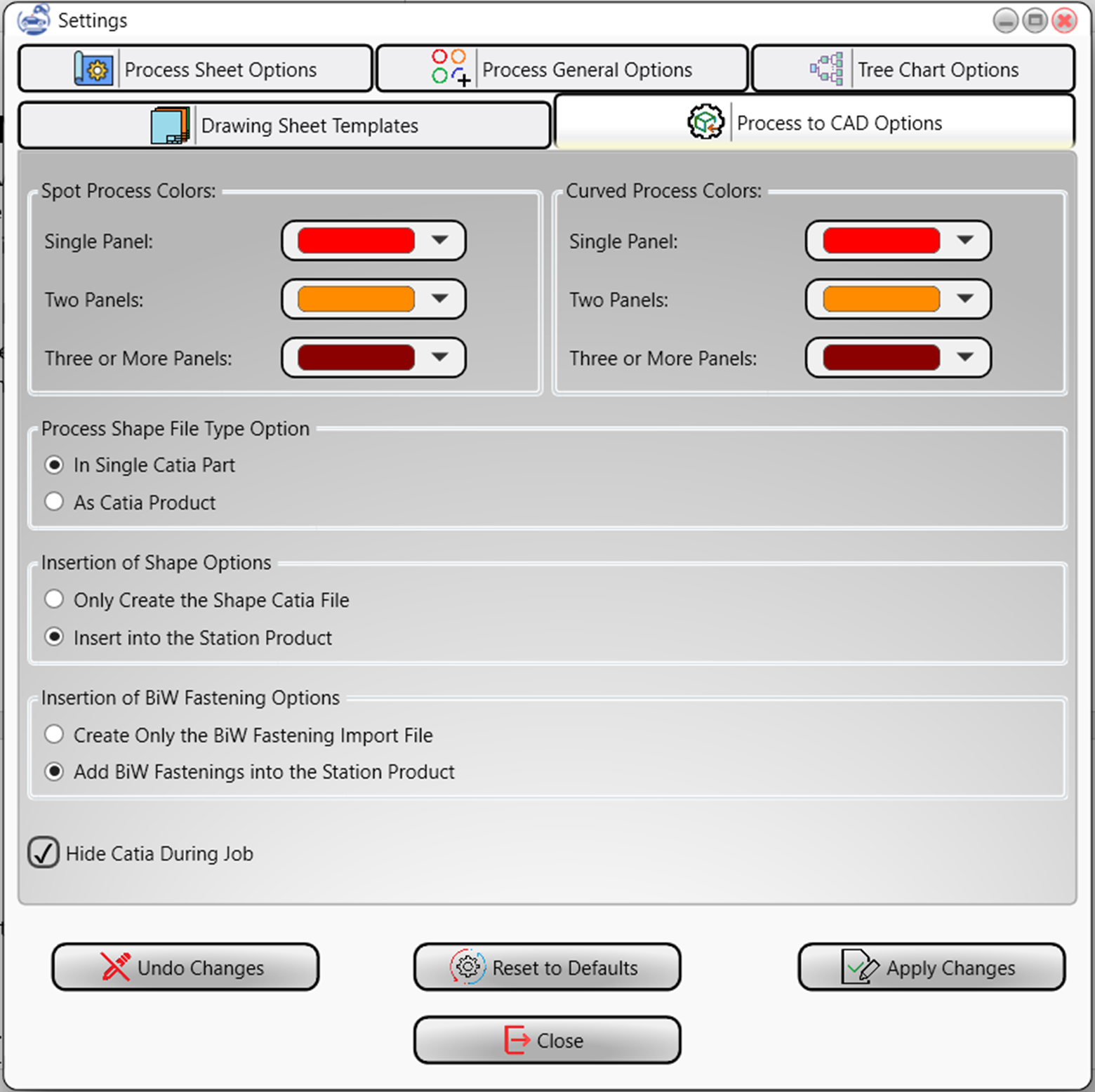

7.1. Create Tree Chart in Excel

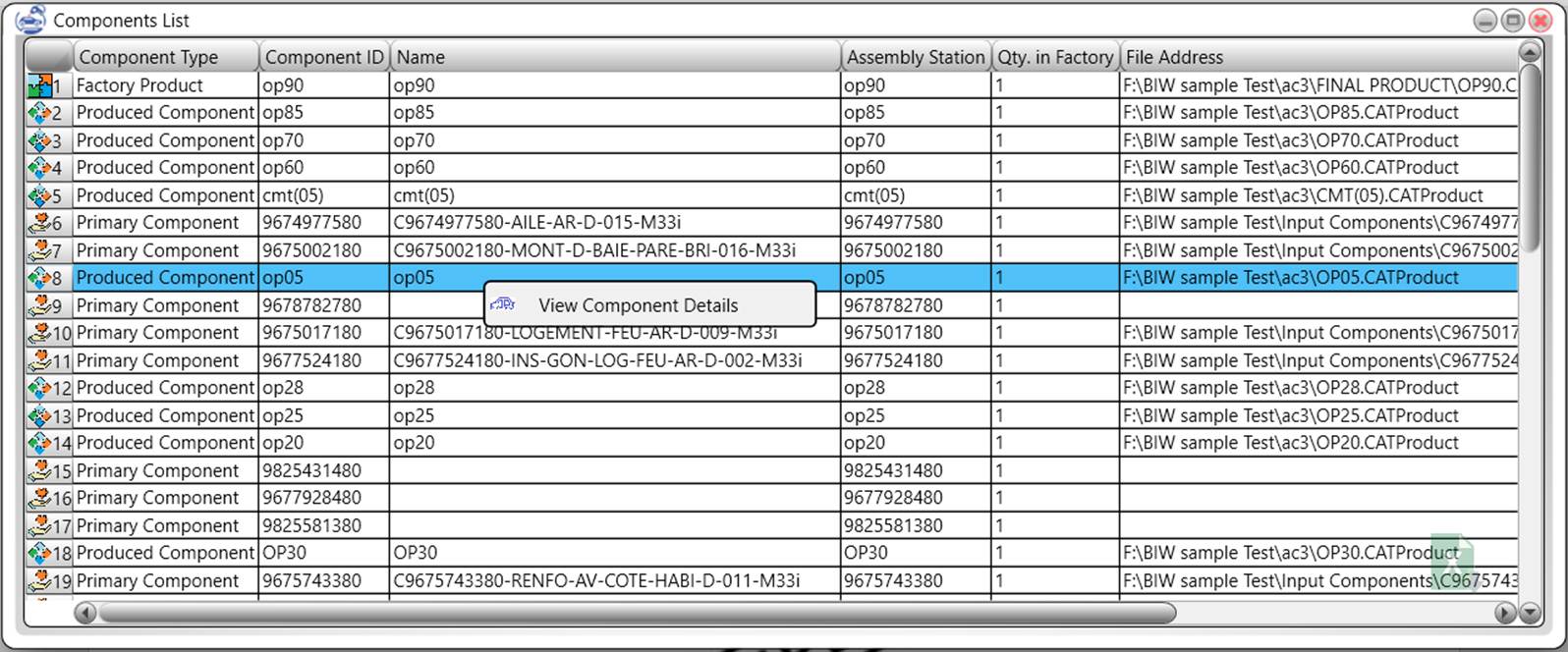

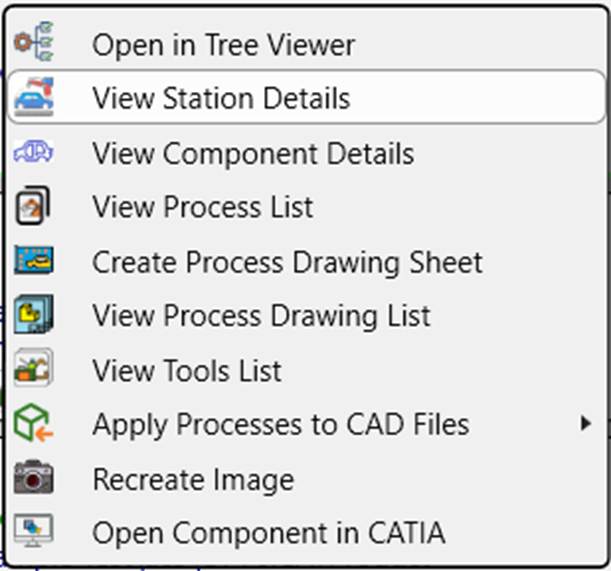

7.2.1. Context Menu of the Node List

7.3.1.

Context Menu of Component List

Viewer

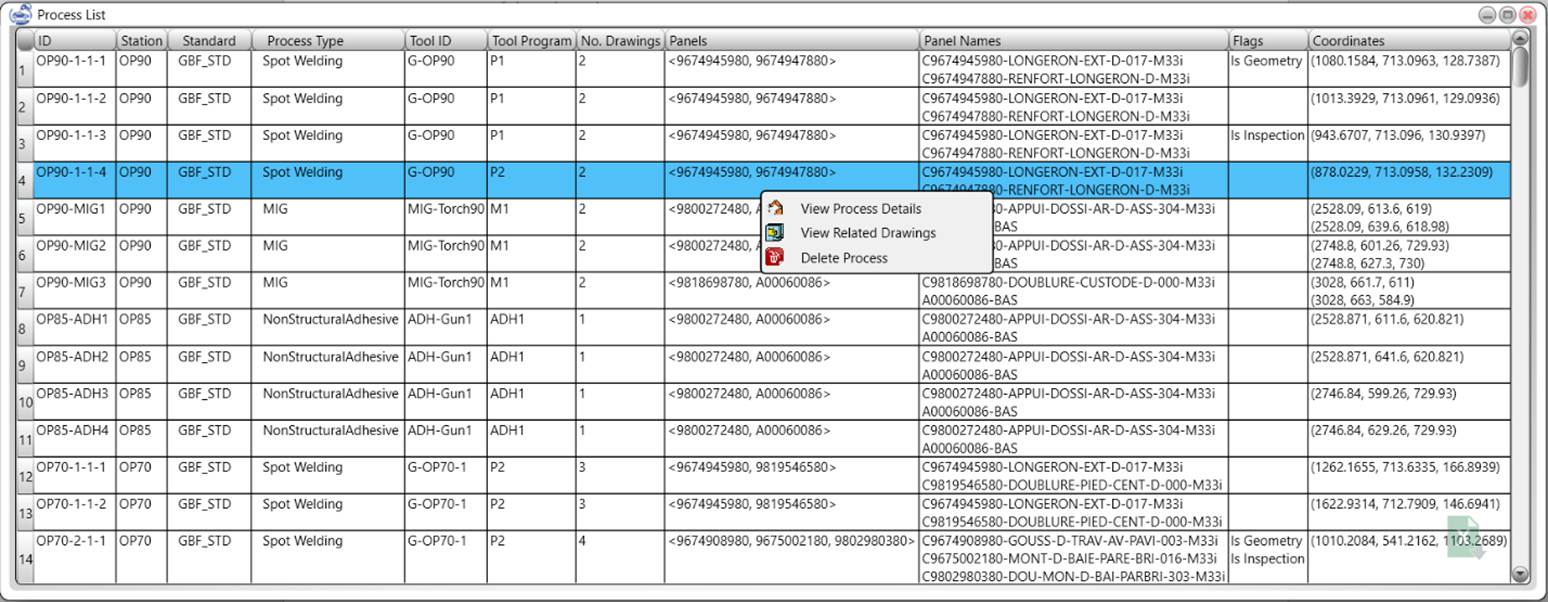

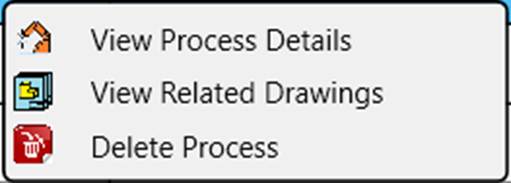

7.4.1.

Context Menu of Process List

Viewer

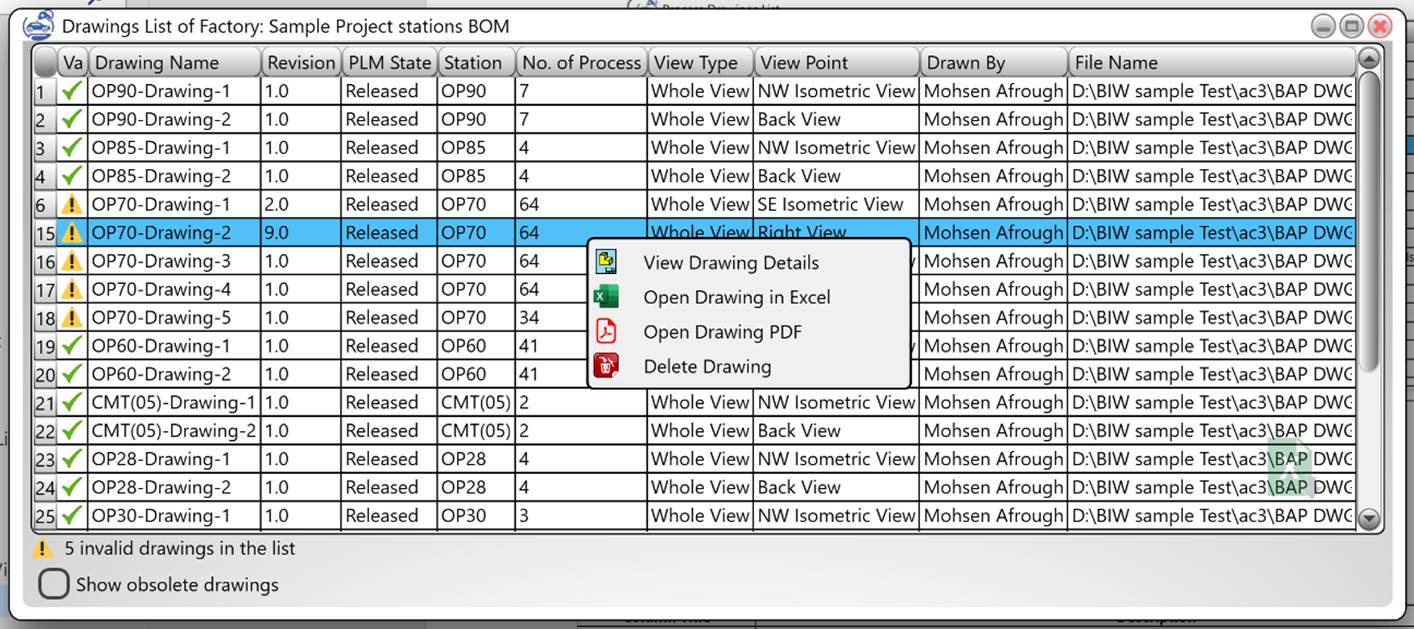

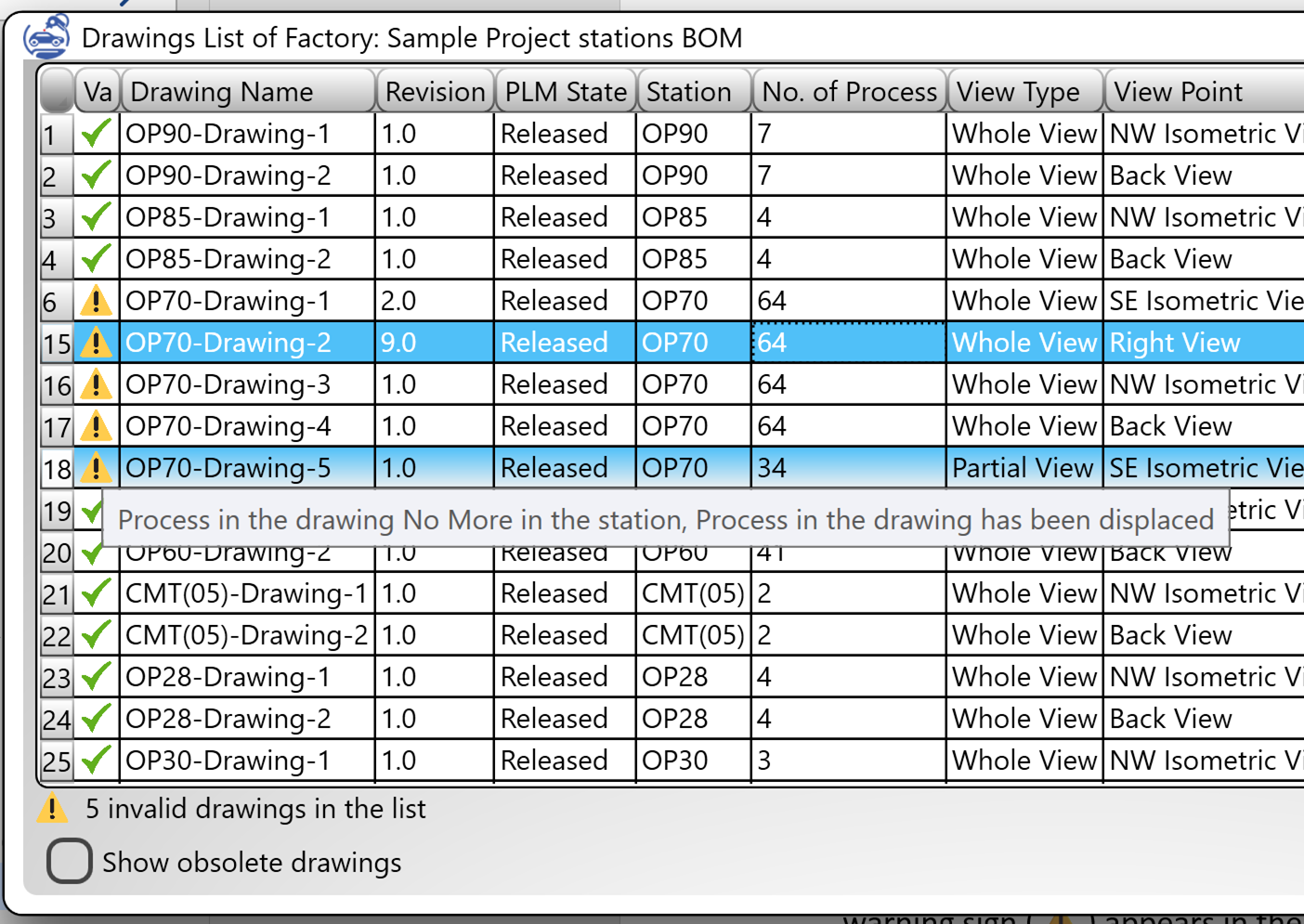

7.5.2. Show and Hide Obsolete Drawings

7.5.3.

Context Menu of the Drawing List

Viewer

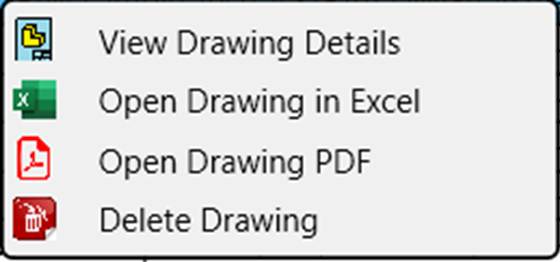

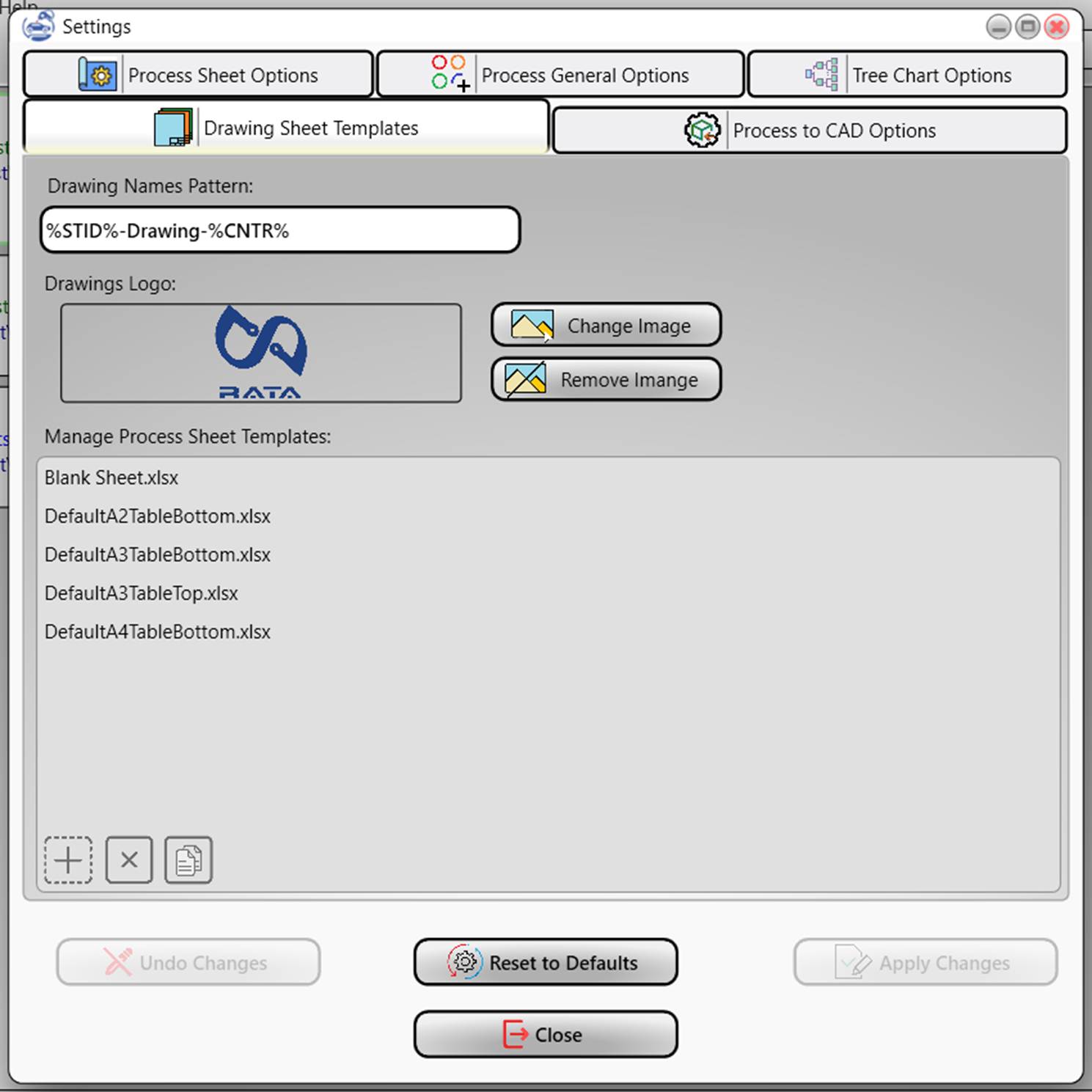

8.1.3. Drawing Sheet Templates Tab

8.1.3.1. Drawing Names Pattern

8.1.3.3. Manage Process Sheet Templates

8.1.3.4. Process Sheet Templates format

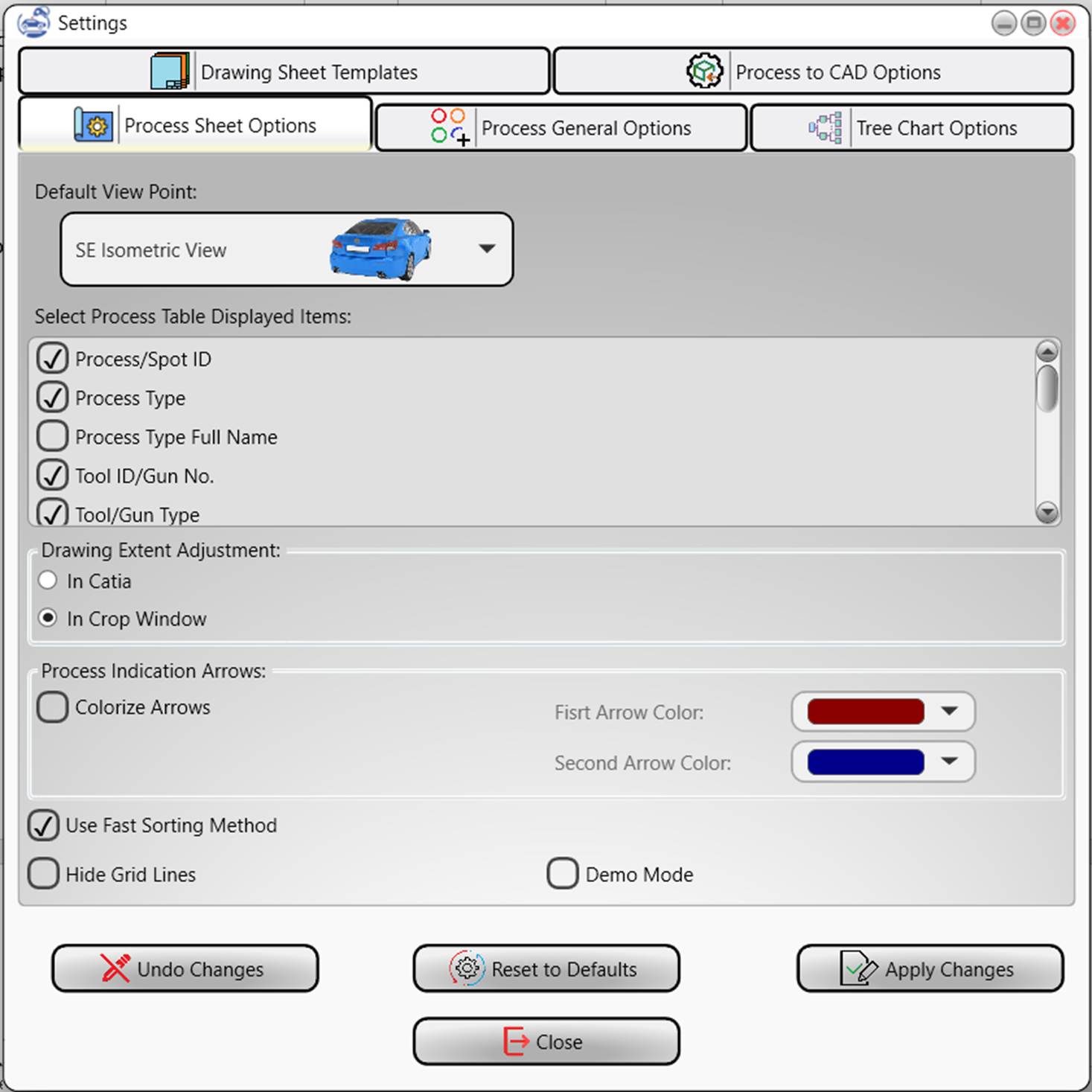

8.1.4. Process Sheet Options Tab

8.1.4.2. Selected Process Table Items

8.1.4.3. Drawing Extent Adjustment

8.1.4.4. Process Indication Arrows

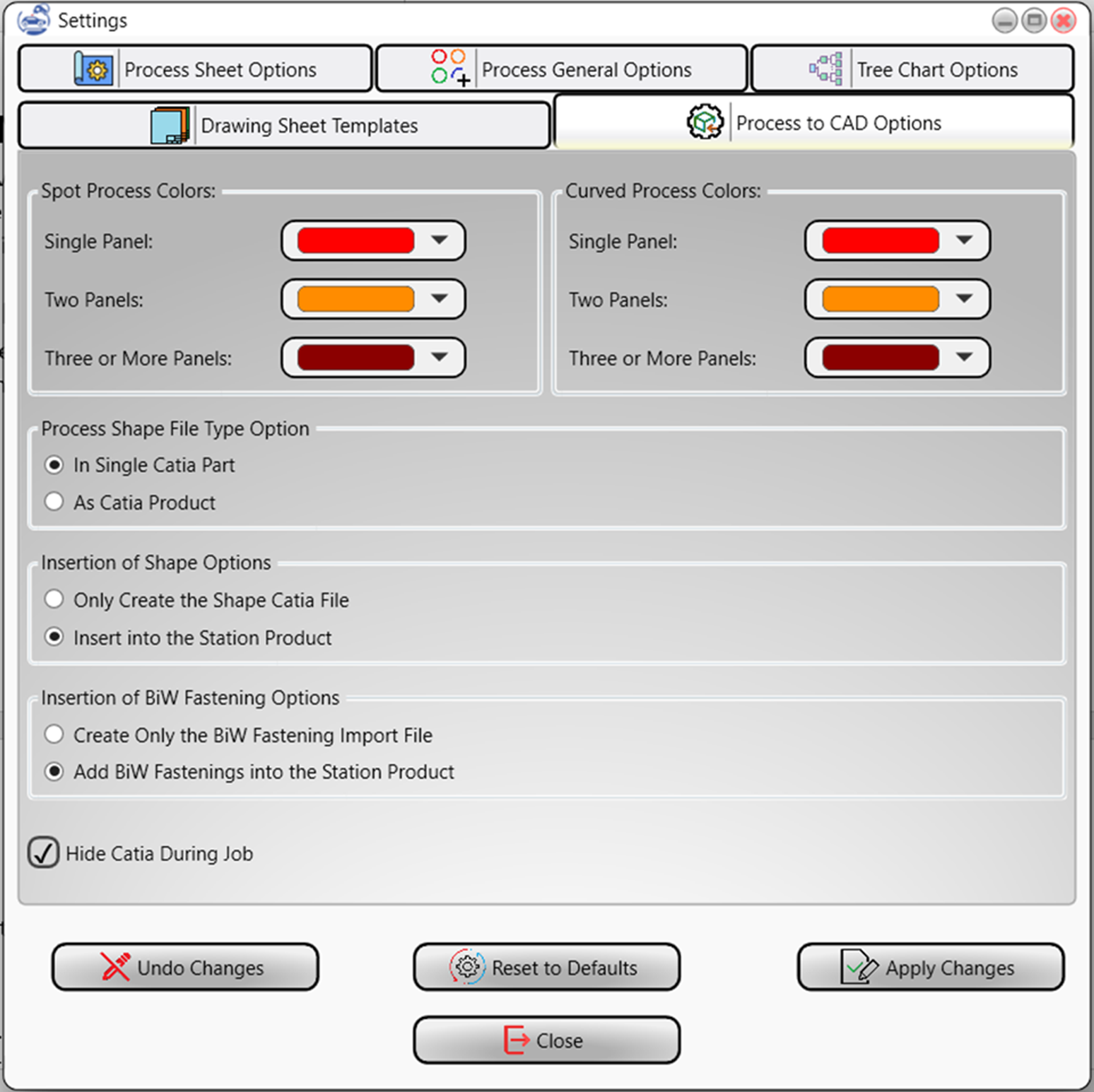

8.1.5. Process to CAD Options Tab

8.1.5.2. Curved Process Colors

8.1.5.3. Process Shape File Type Option

8.1.5.4. Insertion of Shape Options

8.1.5.5.

Insertion of BiW Fastening

Options

8.1.6. Process General Options Tab

8.1.6.1. Process Incorporation Options

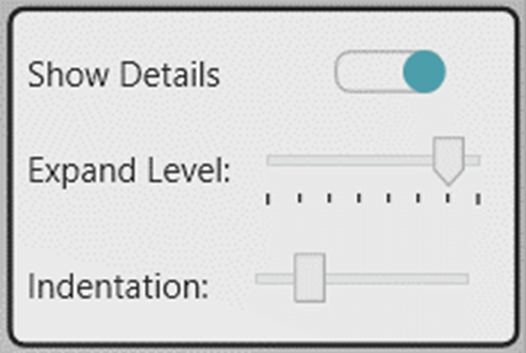

9.2.3. Tree View Settings Menu

9.6.4. Drawing Management Buttons

9.6.4.4.

Locate File in the Drawings

Folder

2.

Introduction

BIW-AP is a software aimed to assist in planning the assembly process in BiW production lines. It helps in visualizing the product family tree and parts assembly sequence, modifying assembly sequence, automatic creation of assembly CATIA product files, planning the production processes like spot welding, sealing etc., adding the defined processes to CATIA files and automatic generation of workshop drawings.

3.

Overview

3.1. Program Functions

3.1.1.

Read or Create CAD Files

According to Plant BOM

BIW-AP program is

intended to create/manage CAD files and process shop drawings of projects of

planning a BiW assembly line. If The CAD files of the

family tree are already created according to the Plant BOM (Manufacturing Bill

of Material) the program can start a project by reading the Plant BOM structure

from the existing CAD files. Otherwise, it can create the CAD files according

to the planned assembly sequence of Plant BOM.

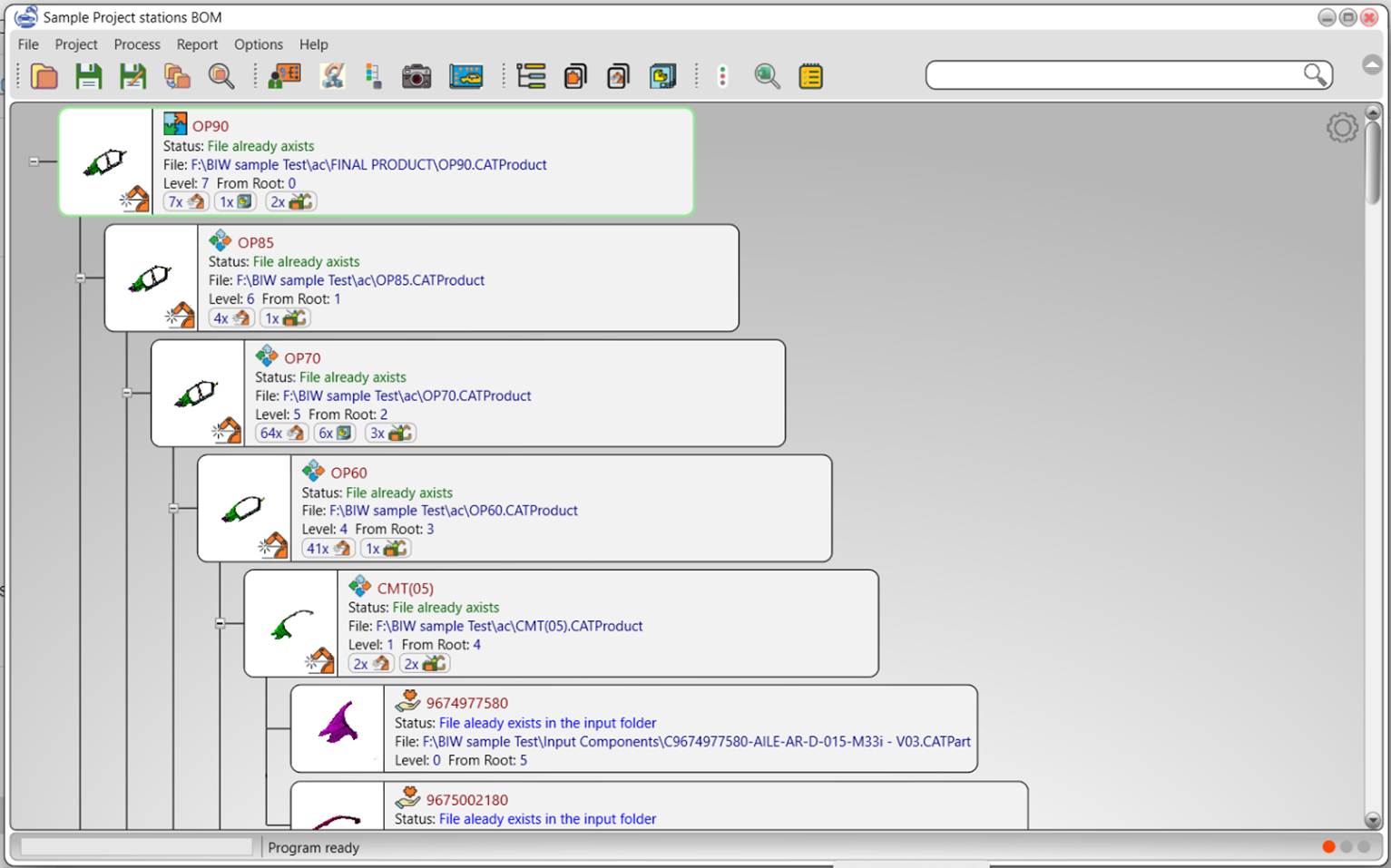

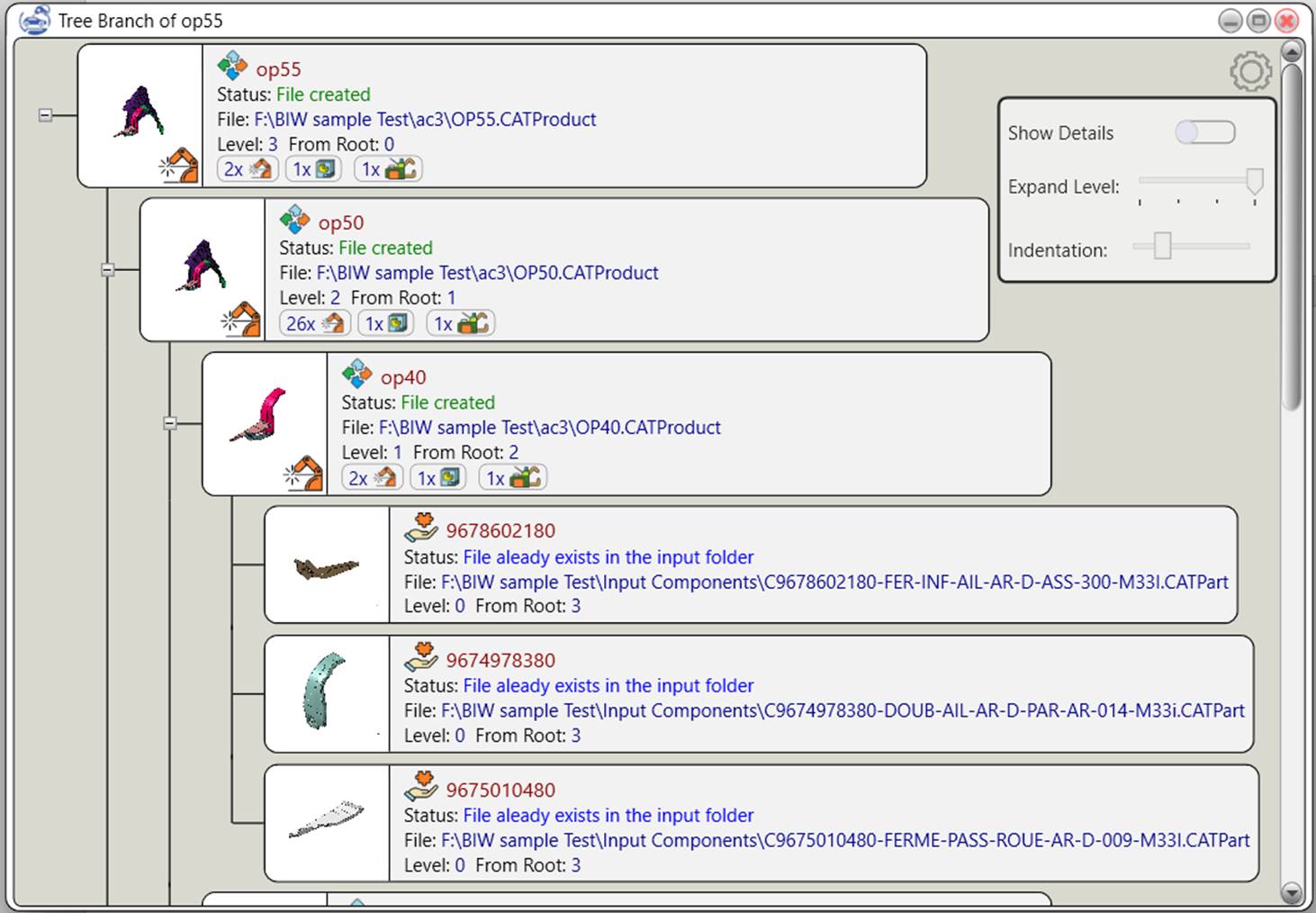

3.1.2. Visualize The Family Tree

Once the Plant BOM is defined

in the program, it visualizes the family tree of the product and accordingly

the image and information of each assembly station. A visual presentation of the family tree

helps in understanding the Plant BOM and find flaws or possibilities of

improvement in the planned Plant BOM. An example of tree view of a project is

shown in

Figure 3‑1

.

Figure

3

‑

1

A Family Tree View in BIW-AP Program

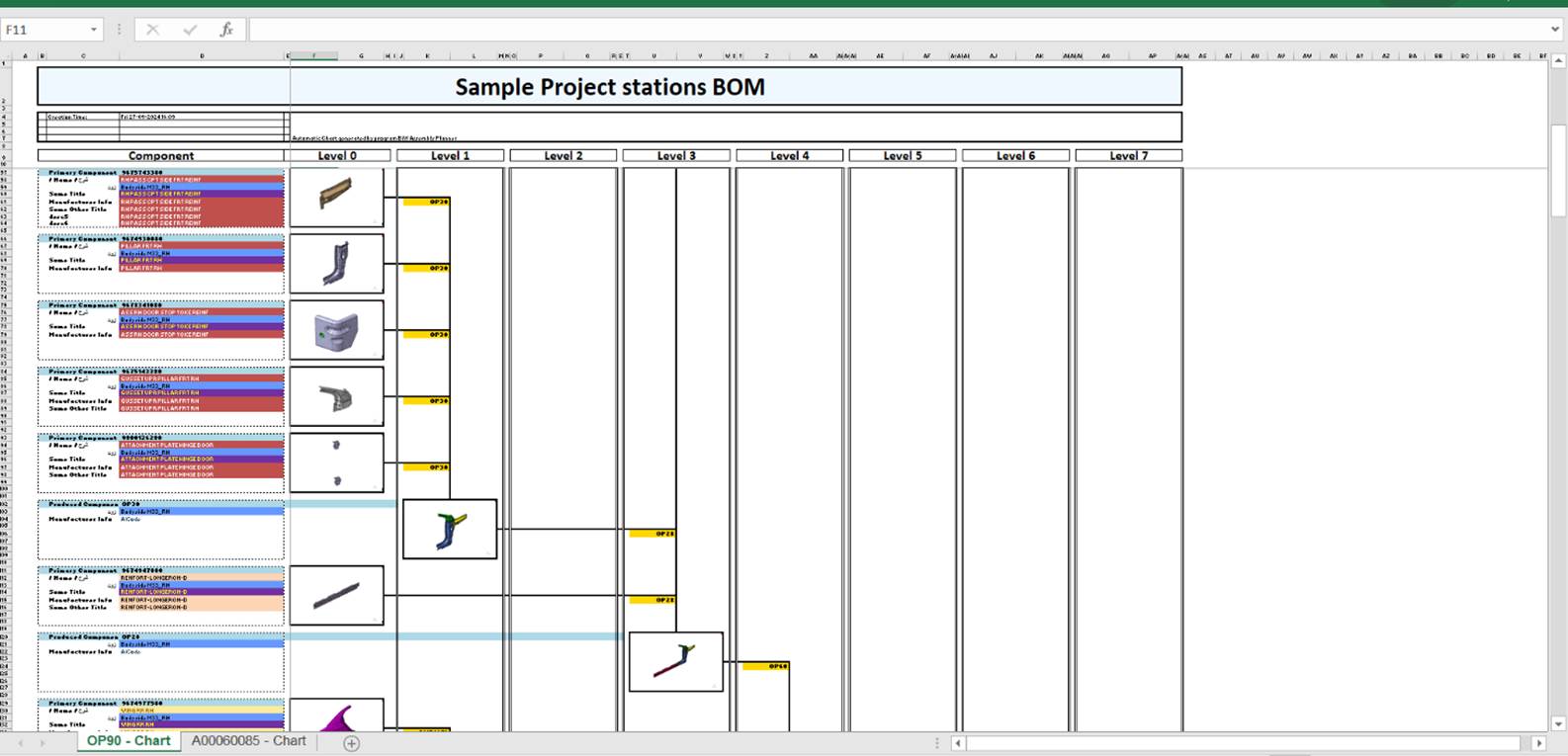

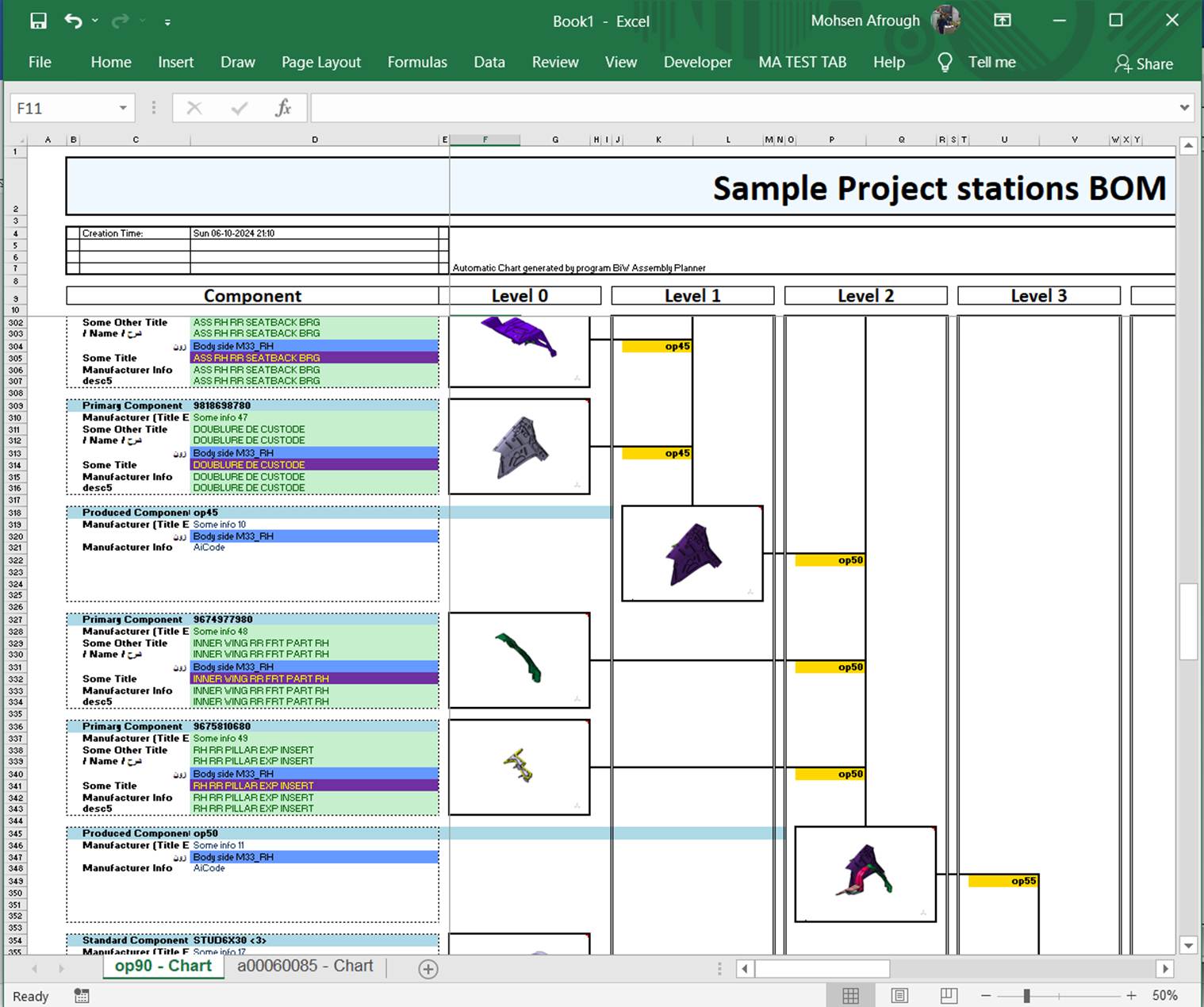

3.1.3.

Create Family Tree Chart

in Excel

The family tree chart in Excel

which is a typical document in automotive industry for illustration of the BiW assembly plan and is required for communication with

suppliers and different departments is made by the program. Manual creation of

this chart is a cumbersome job which is now made easy as a click by this

program and saves a considerable time in engineering of the BiW

assembly lines. An Example of family tree chart created by BIW-AP is shown in

Figure 3‑2

.

Figure

3

‑

2

An automatic generated family tree Excel chart

3.1.4. Definition of Processes

Manufacturing processes

at each station of the assembly line can be defined in the program either by

importing from a excel file or reading from BiW

Fastening definition in Catia CAD Files.

3.1.5. Creation of Process Sheet Drawings

Process drawings are one

of the goals of engineering of BiW assembly lines.

These drawings are needed for programing the tools and teaching the robots and

training of the production personnel. These drawings are also needed as

documents needed for repair and maintenance of the BiW

lines during the production life cycle.

Since the construction

and production technicians are the main users of the process drawings, and

these people usually have no access to expensive software like Catia, the

process drawings are preferred to be made in general software like Excel to be

available to the users, and also be editable by them to keep them handy and

updated during the product life cycle.

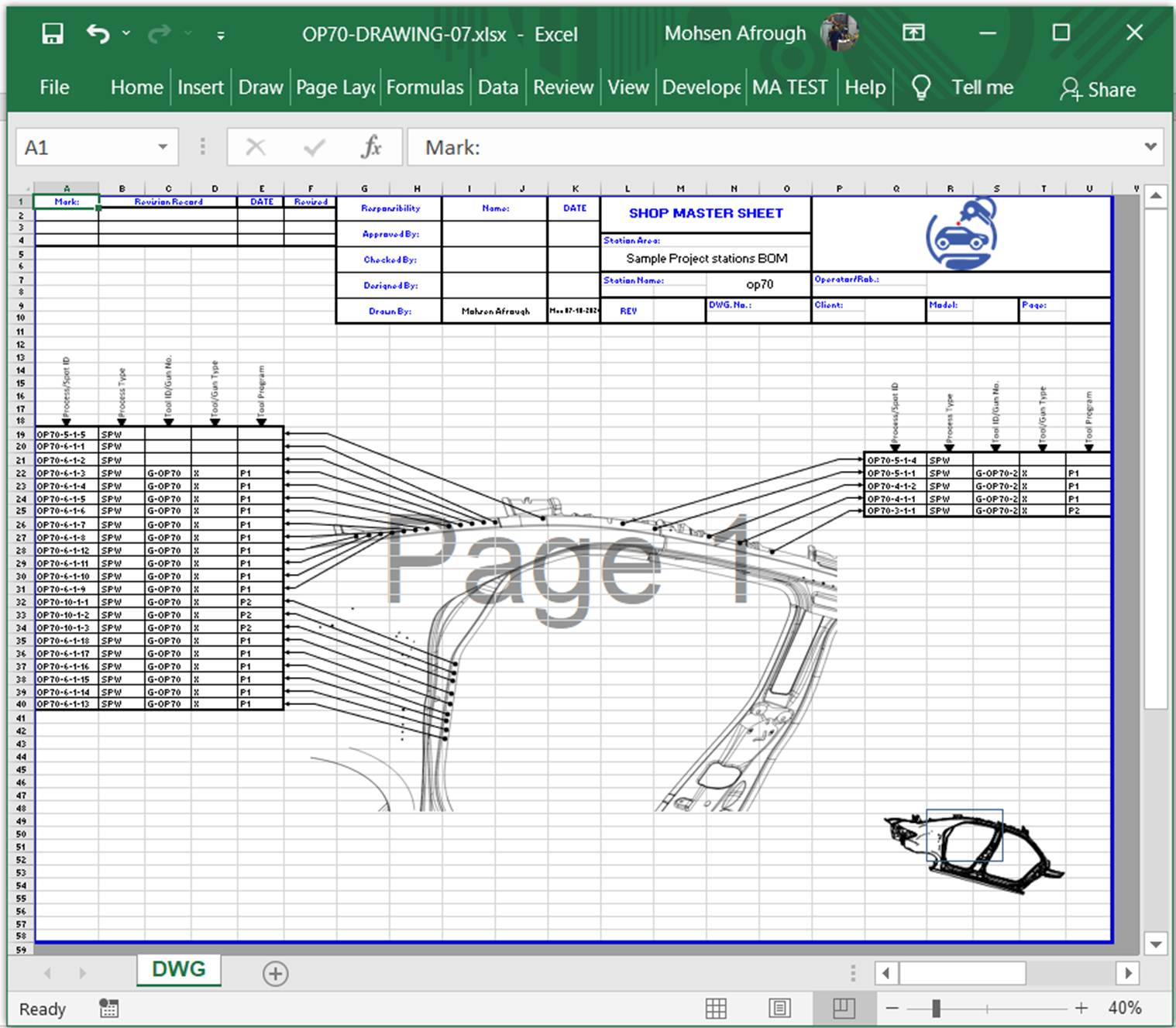

Creation of process

drawings is a meticulous, cumbersome and exacting job which is very prone to

mistakes. The BIW-AP program makes the creation of drawings as easy as a click

for dozens of drawings. The drawings are created both in Excel and PDF

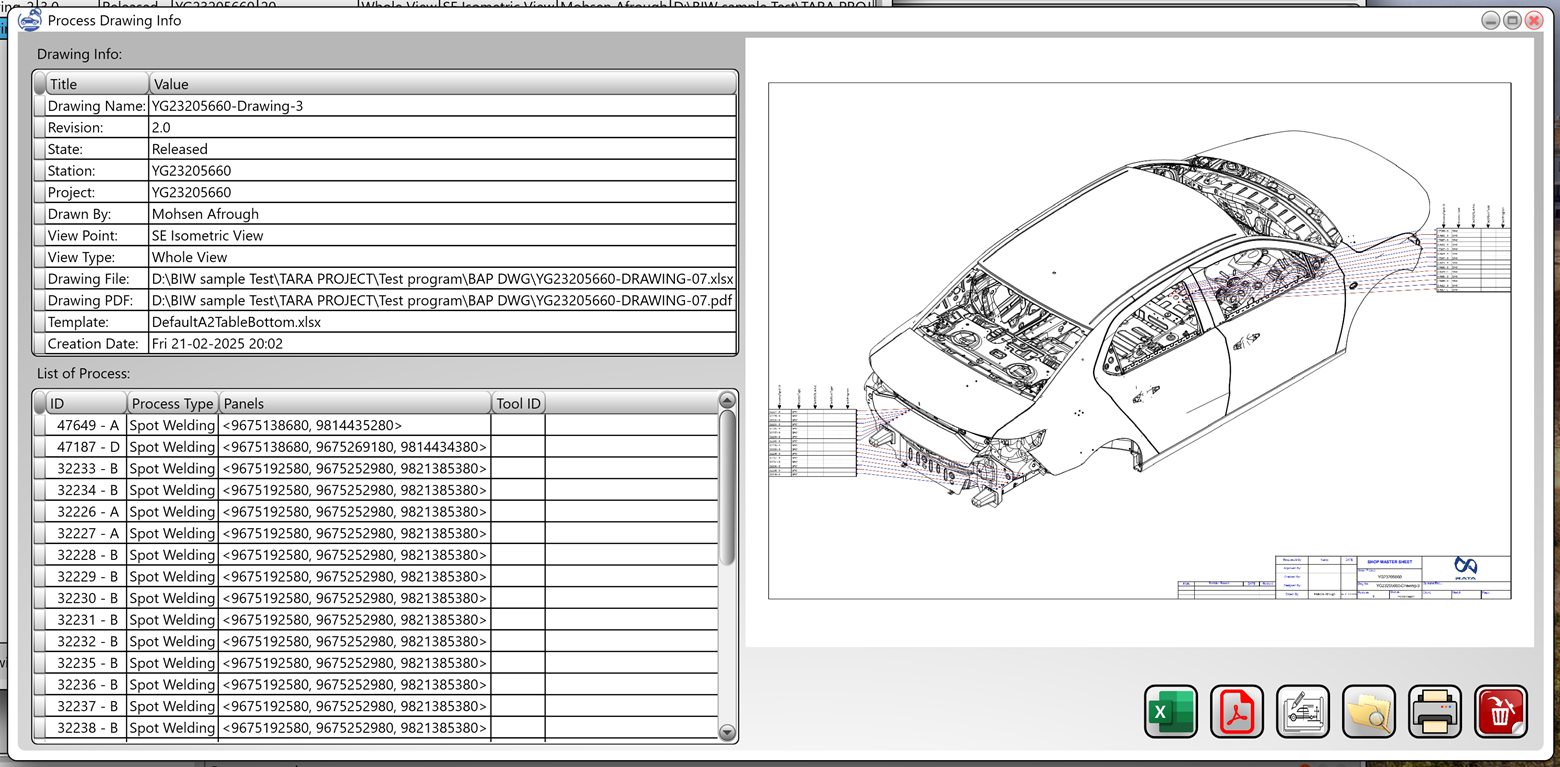

documents. A sample of automatic in excel created process drawings is shown in

Figure 3‑3

.

Figure

3

‑

3

Samples of automatic generated

process drawings

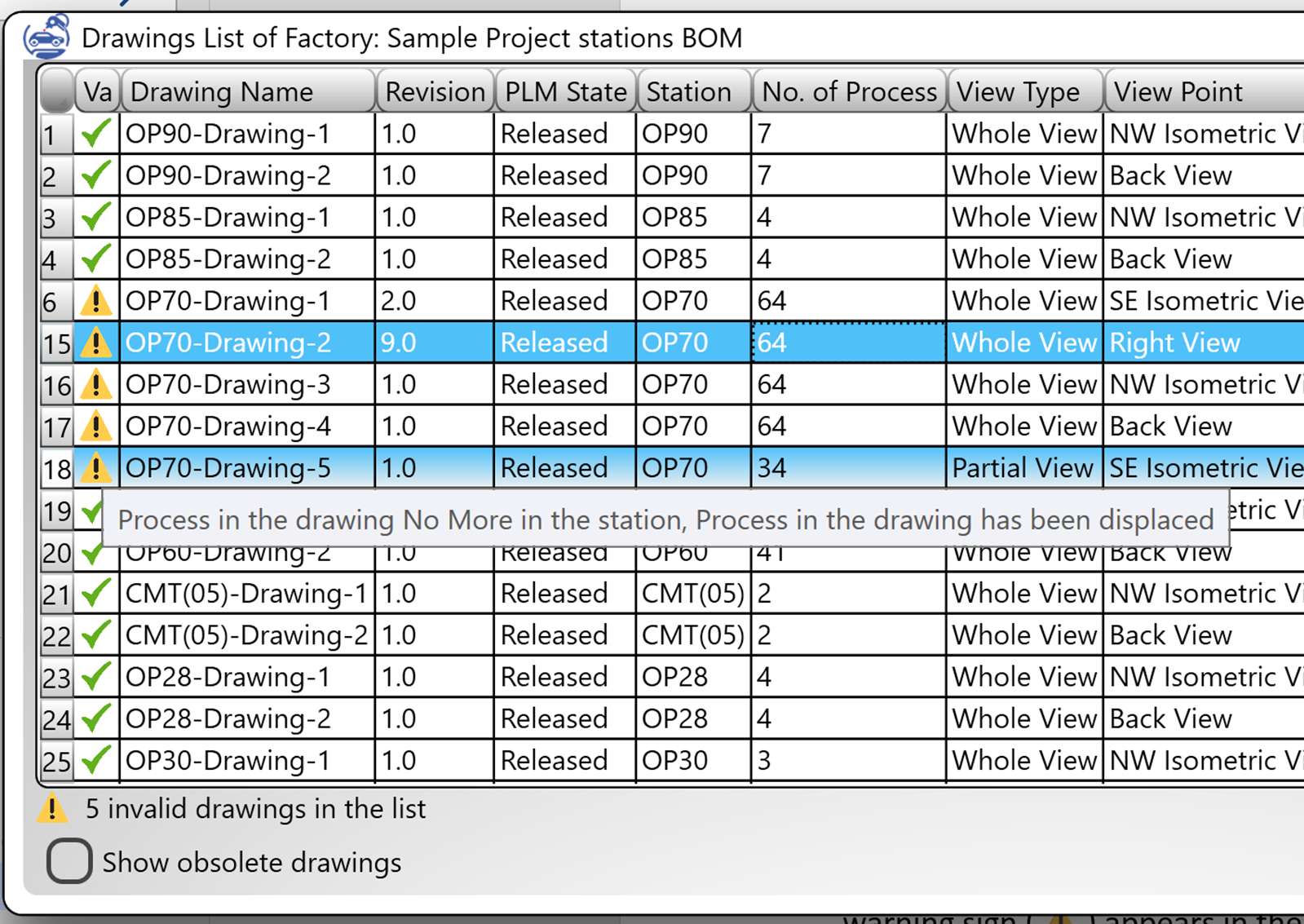

3.1.6.

Validation of Drawings by

Tracking the Changes in Process Plan

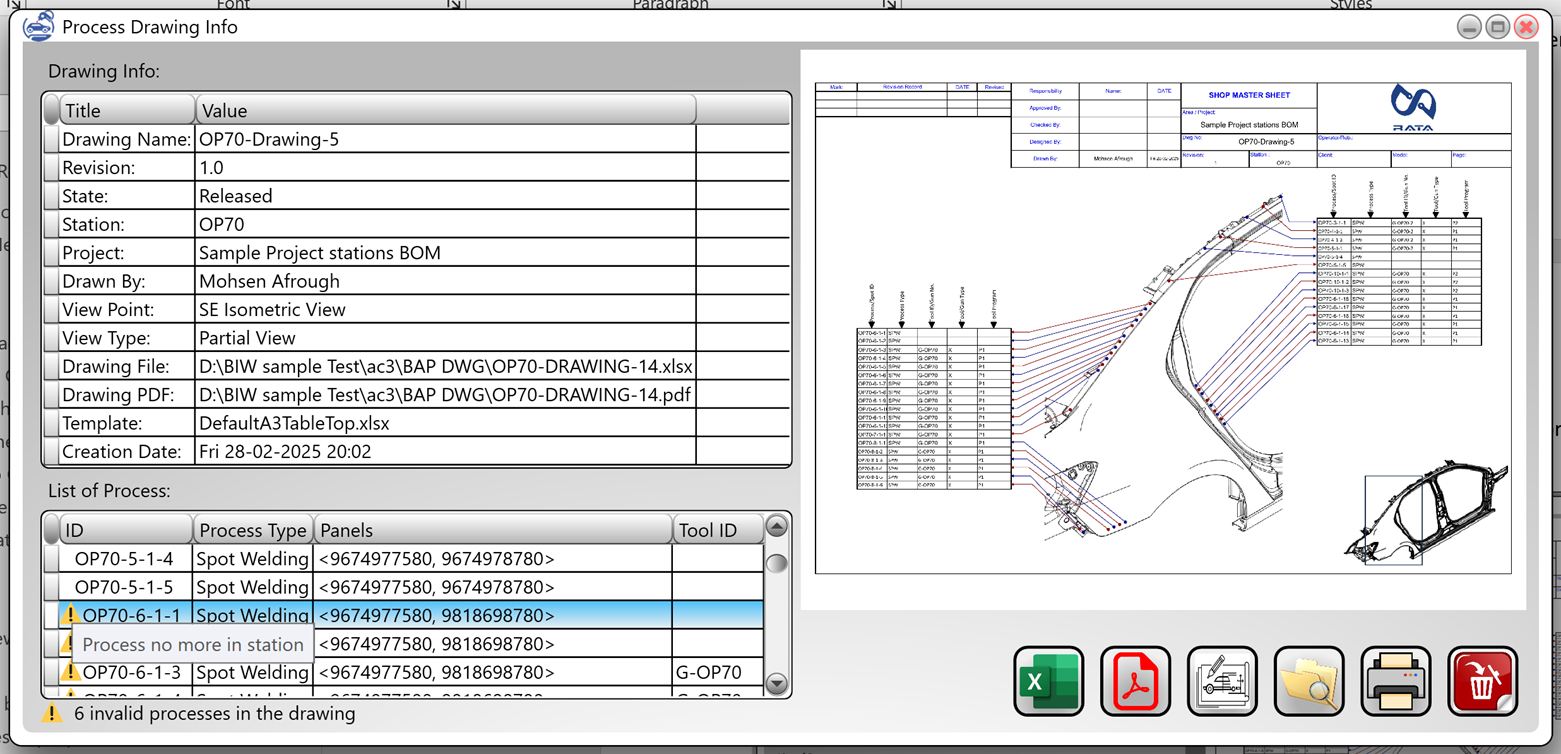

It is a tremendous job to keep them updated

during the Plant BOM planning and keep track of changes in the process in

drawings. This program keeps the drawings continuously updated and warns if any

changes in stations or process definitions invalidate any of drawings. The changes in the drawing validations

automatically and immediately reflect in the listing and reports. Invalidated

drawings, appear with a warning sign (

⚠️) in the listing reports.

Figure

3

‑

4

Invalidated Drawing in a

listing report

3.1.7. Movability

The program updates its

data with the existing files in the project folder. Therefore, just copying the

files or drawing folder to the folder of a new project is enough for

transferring the data or synchronizing the data with the new project. Of

course, the data will be checked for consistency and validation when they are

loaded to the project.

3.2. Program User Interface

The program interface

provides visual facilities for viewing project data and performing desired task

on the project.

Figure 3 ‑ 5 Program Interface

3.2.1. Data View Area

Data view area is the

largest part of the program window. In the data view area of the program the

family tree structure of components produced in the BiW

assembly line is shown. Each station in the BiW line

comprises a node in the tree which gives a brief overview of the station

information in a bubble. On the left side of the bubble a picture of the

assembled component in the station is shown if available. More details of each

station can be seen by adjusting the setting in the view settings menu. The view

settings menu pops up when clicking on the gear sign (

![]() )

on the top right side of the data view area. A glimpse of the Data View Area is

shown in

Figure 3‑5

. Tree viewer details is

explained in section

9.2

.

)

on the top right side of the data view area. A glimpse of the Data View Area is

shown in

Figure 3‑5

. Tree viewer details is

explained in section

9.2

.

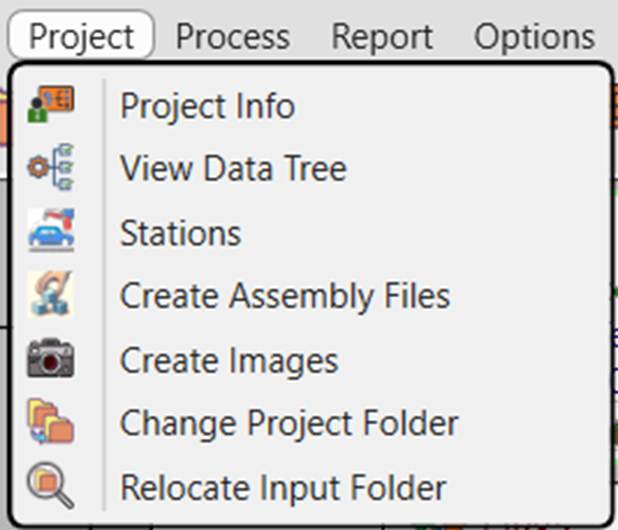

3.2.2. Top Menu Bar

The top menu bar of the

program includes menu headers of File, Project, Process, Report, Tools and

help. Each of these menu headers pops a menu with related items. The file menu

includes items for creation of s new project, save and open item and exit the

program.

The project menu includes

items for viewing or manipulating project information and creation of assembly

components.

The process menu includes

items for adding or removing process items to stations in the factory project

and creation of process shop drawings.

The report menu generates

list reports of the project data including reports of components, stations and

process and drawings. The reports are generated in sub windows in the program

but option for export to excel is available if required. One of items in the

report menu also creates the family tree chart in an excel sheet.

In the Tools menu an item

is available for checking the connection to Catia program, and item for

unhiding excel program if excel runs in hidden mode and the options item is

available through this menu which allows adjust program and project settings.

The help menu provides

the instruction of the program including this help document.

3.2.3. Search Bar

A search box appears on

top right side of the program along with the menu bar. This search bar can be

used to find nodes in the family tree view. If the sought node is in a

collapsed branch of the tree the branch is expanded and the found node bubble

is shown as the selected node.

3.2.4. Status Bar

Status bar is the ribbon

on bottom of the program main window. The status bar includes a progress bar

that indicates the progress of the running task of program, the status text

area which shows the messages of the program, and the Catia status indicator

which continuously shows the Catia connection status.

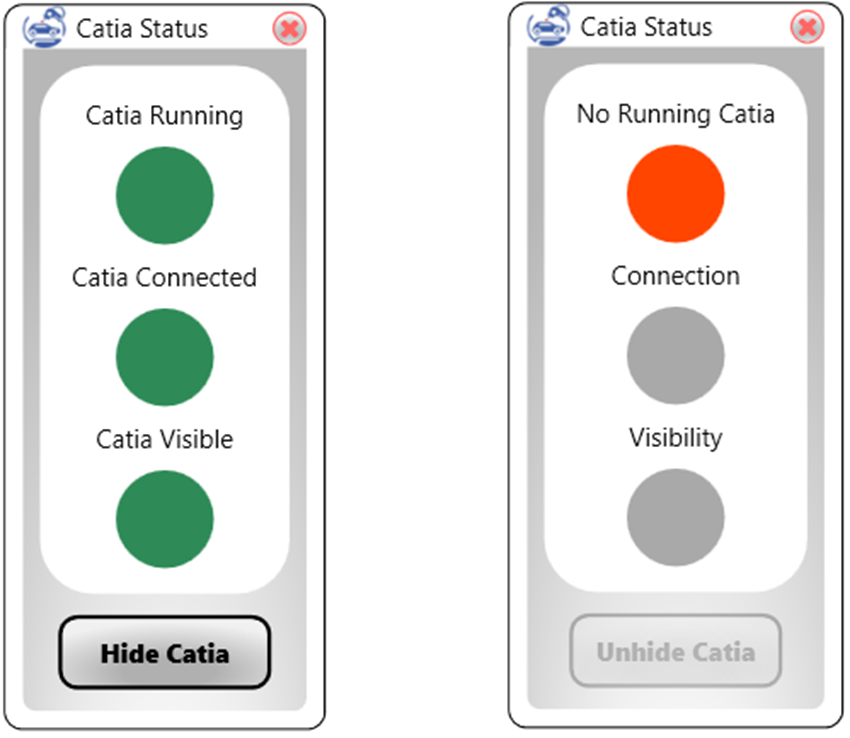

3.2.5. Catia Status Indicator

The Catia status

indicator comprises three big dots on bottom right of the main window. The first dot from left indicates if Catia is

running on the computer. If no instance of Catia is running it is red and the

other two are gray. As soon as an instance of Catia is started on the computer

this first dot turns green and the second dot turns red, which indicates that

Catia is not connected yet. When Catia is fully loaded and BIW-AP program

succeeds in connecting to it, the second dot turns green too.

The last dot on the right

side is green whenever Catia is visible and red if Catia is running in

invisible mode. Some of program operations hide or unhide Catia, but a manual

control is also available in “Catia Status Watcher” window through options menu

(see sec.

8.2

).

3.2.6. Node Types

There are five node types

in product family tree as listed in the

Table 3‑1

:

Table 3 ‑ 1 Node Types

|

Icon |

Node

Type |

Description |

|

|

Factory

Product |

Factory products are the final

products of the BiW Assembly line considered as the

output of the line. A project should have at least one factory product. The

program allows to define more than one factory product. |

|

|

Primary

Component |

Primary component is a component

already produced and fed to the assembly line.

A Primary component appears only

once in the factory product.

A primary Component can be a

body panel with a CATPart type CAD file or a

complex assembled structure in a CATProduct file.

However, if it’s a CATProduct no operation on the

sub parts of it are allowed in the project. If operations on sub parts are

intended then a subassembly node type should be defined for it. |

|

|

Subassembly

Component |

Subassembly component is an

assembly of some parts presented by a CATProduct

CAD file used several times as different positions in the factory product.

Further operations like welding of subassembly panels at the insertion

positions is allowed in the program. |

|

|

Standard

Part |

Standard part is a component

already produced and fed to the assembly line.

Unlike primary components, a

standard part may appear more than once in the factory product.

A primary Component can be a

body panel with a CATPart type CAD file or a

complex assembled structure in a CATProduct file.

However, if it’s a CATProduct no operation on the

sub parts of it are allowed in the project. If operations on sub parts are

intended then a subassembly node type should be defined for it. |

|

|

Subassembly

Instance |

Subassembly instance is a node

in the family tree of the factory product where an instance of a subassembly

is inserted. The ID of the node

comprises the ID of the subassembly followed by its instance number embraced

in “<>”, e.g., “A0050089<1>” |

|

|

Standard

Part Instance |

Standard part instance is a node

in the product family tree where an instance of a standard part in

inserted. The ID of the node comprises

the ID of the standard part followed by its instance number embraced in “<>”,

e.g., “SUDT8x12<1>” |

|

|

Produced

Component |

Produced components are

components that are produced by assembling several other components together

in the BiW assembly line. |

Note:

The nodes of types Factory Product,

Subassembly Component and Produced Component are actually corresponding to

working stations in the BiW Assembly line, hence

called also stations.

The station nodes can

have manufacturing process definitions. i.e., manufacturing processes like spot

welding or other type of welding, addition of adhesives, mechanical joining and

etc. can be defined for station nodes.

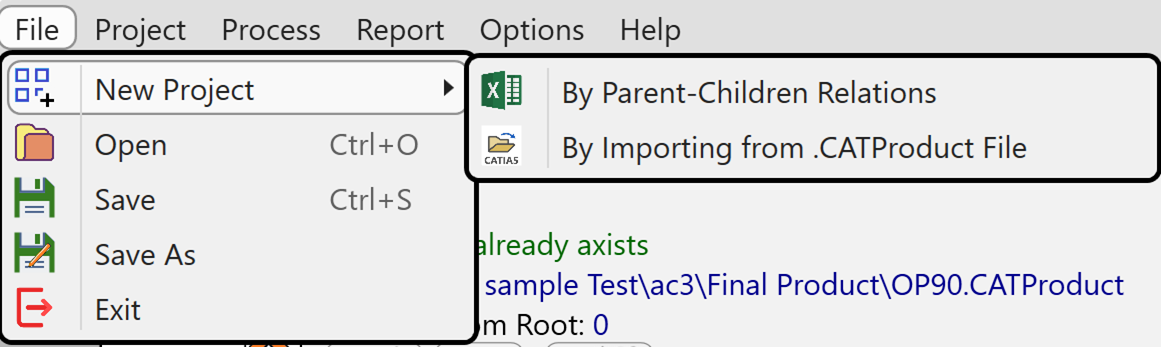

4.

File Menu

File Menu provides general functions for staring a new project, opening and closing a project file as well as saving operations.

Figure 4 ‑ 1 File Menu

4.1. New project

There are several ways to

start a new project that are included in the new project menu item.

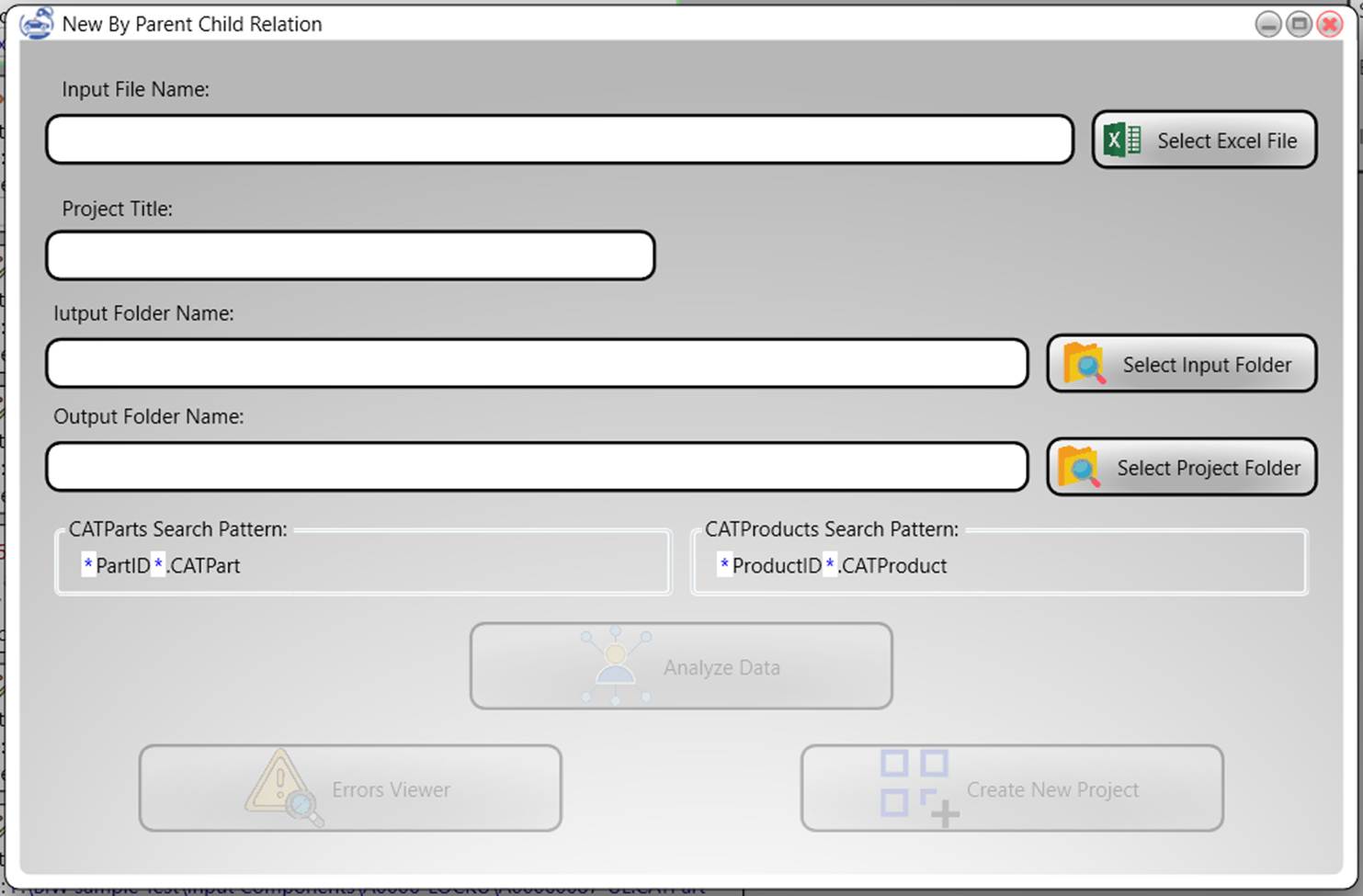

4.1.1. New by Parent Children

In this method the parent-child relations of the

family tree components should be defined in an Excel sheet. By clicking on this

menu item, a new project dialog box as shown in

Figure 4‑2

opens.

Figure 4 ‑ 2 New By Parent Children Dialogue

In this dialog box there are input fields for entering the Excel file name, two fields for defining the file search pattern for CATPart and CATProduct file types, Input folder in which the Catia files of the product components are stored and a folder as the project folder in which all the files created by BIW-AP Program including assembly files, images and temporary files are stored.

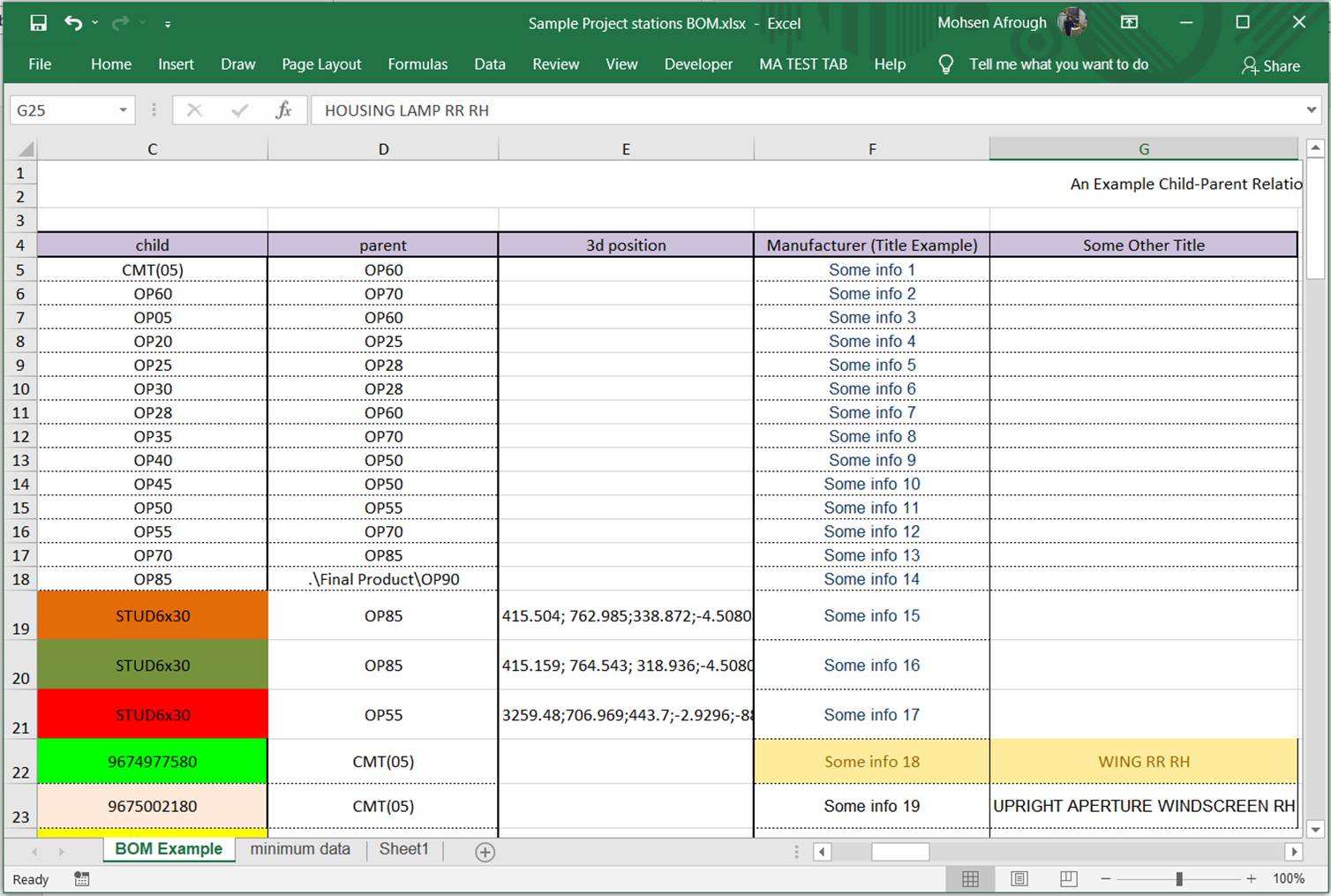

4.1.1.1. Parent Children Excel Sheet Format

The definition sheet should include two columns

with the titles “Parent” and “Child” respectively. A column titled “3D

Position” is optional. Following points should be considered in preparation of

Child-Parent definition excel file:

·

The input sheet should be the first sheet in the Excel workbook.

·

The first row in the excel file that includes both “Parent” and “Child”

cells is considered as the table title row.

·

All rows and data above the table title are ignored by the program. So, the

rows above the table titles can be used for arbitrary notes by user.

·

The table rows need not to be in a sorted order. All the need is the

child-parent relations to be logical and correct, however, for ease of

controlling the accuracy of data it is recommended that the user create the

table in a sorted and classified manner.

·

Any column with a blank cell in the title row will be ignored by the

program.

·

Some properties can be defined for the child components by adding more

columns to the table. For this purpose, the property name should be included

the title row and the property value in the corresponding row of the intended

child. fill and text colors of the property cell are also read and used by the

program as the colors of the property.

·

A sample child-parent sheet is shown in the

Figure 4‑3

.

Figure

4

‑

3

Sample Child Parent Sheet

·

A sample Excel file of child-parent definition can

be retrieved from program from the menu path Tools>Sample Excel Files>Child-Parent

Definition

Child and Parent input formats

The suitable way to

introduce each child or parents can be given chosen from one of different

formats explained in the following table with examples:

Table 4 ‑ 1 Child and Parent input formats

|

Entered

Value |

Example |

Result |

|

ID or Item Key |

AB002556L |

A Catia file corresponding to

the given ID is searched for according to the search pattern. The Search is

done in the “input folder” and the “Project Folder” respectively. |

|

Full file name |

E:\CatiaComponents\PN-AB002556L-Outer.CATPart |

The given file is searched for. |

|

File name |

PN-AB002556L-Outer.CATPart |

The given file name is searched

for in the “input folder” and the “project folder” respectively. |

|

“CATPart”

File name with relative address in CHILD column |

.\Some Subfolder\

PN-AB002556L-Outer.CATPart |

The given file is searched in

the given subfolder respectively in the “input folder” and the “Project

Folder” |

|

“CATProduct”

File name with relative address in PARENT column |

.\Some Subfolder\PN-AB002556L-Outer.CAT.CATProduct |

The given file is searched in

the given subfolder respectively in the “input folder” and the “Project

Folder”. If the component is not found, the subfolder will be created in the

project folder and the assembly file will be created in it. |

|

ID or Item Key with relative

address |

.\Some Subfolder\AB002556L |

A Catia file corresponding to

the given ID is searched for according to the search pattern. The Search is

done in in the given subfolder in the “input folder” and the “Project Folder”

respectively. If The If the component is not a primary component and not

found, the subfolder will be created in the project folder and the assembly

file will be created in it.

|

Note:

In addition to the file address, a color can be

assigned to the child component by assigning a fill color to the child

definition cell. This fill color will be used as the color of the component in

creation of Catia assembly files by the program.

3D Positon input Format

The 3D position of each

component indicates the position and orientation of the child component in the

parent assembly. If the 3D position of a child is left blank the child is

inserted in the assembly CAD file in the same coordinate system as the parent’s

which is usually the Car Coordinate System in the automotive industry.

There are two different

ways for entering the 3D position, by 6 or 12 coordinate components. The

coordinate components are in either way separated by a semicolon “;”.

·

In 6-component format of the 3D position the first three components

indicate the origin of the coordinate system and the three remaining components

indicate the orientation of the coordinate system by three rotation angles

respectively about X, Y and Z axes of the parent coordinate system. i.e., the

coordinate system is given as: “

X; Y; Z; RotX; RotY;

RotZ”

·

In 6-component format, the rotation angels are given in degrees.

·

In 12 component format the coordinates of the unit vectors of the child

coordinate system axes with respect to the parent coordinate system come first

and then the coordinates of the origin of the coordinate system. i.e., the

coordinate system is given as: “Ux

; Uy; Uz;

Vx; Vy; Vz; Wx; Wy; Wz; X; Y; Z”

Hint:

A simple way to extract the position coordinates

of a component in Catia is to open the parent “CATProduct”

file in Catia. Then temporarily apply a “Fix” constraint on the component you

need the coordinates of (i.e., by icon

![]() ).

Now you can open the “Constraint Definition” window of the added constraint by

double clicking on its anchor sign. the 6 coordinate components can be seen in

the opened dialogue box, by clicking on the “More>>” button.

).

Now you can open the “Constraint Definition” window of the added constraint by

double clicking on its anchor sign. the 6 coordinate components can be seen in

the opened dialogue box, by clicking on the “More>>” button.

Figure

4

‑

4

Components of coordinate

system in CATIA

Additional Property Definition

Any desired number of

properties can be defined for the child components by adding more columns to

the table. For this purpose, the property name should be included the title row

and the property value in the corresponding row of the intended child.

·

Fill color and text color of the property cell are also read and used by

the program as the colors of the property.

·

If a row comprises only one of either child or parent (i.e., either Child

cell or parent cell in a row are left blank) the row is considered as a

property definition row. The properties given in the row are attributed to the

given component in the child or parent column.

·

If a property is given more than once for a child the last row definition

is taken by the program.

4.1.1.2. Input folder

If the full file address of a component is not given in the excel sheet, the program first searches for it in the “input folder.” So, the primary components of the product family tree can be placed in a folder and introduced as input folder to the program

4.1.1.3. Project Folder

If a component is not found in the input folder it will be searched for in the “Project Folder” by program. If the component is not found in the project folder it will be created in the project folder.

· In addition to the Catia components, the project folder is where all created data of the project including drawings, images, process components, export files and temporary files will be created in.

· Images of the components will be created in a subfolder named “images” in the project folder

· Process drawings including Excel drawing files, PDF files and Jpeg or PNG files will be created in a subfolder named “BAP DWG” in the project folder.

· Process shapes are created in a subfolder named as the corresponding component file name in the project folder.

· Catia process export files will be created in the project folder with the same file name as the corresponding component with a “.txt” extension.

4.1.1.4. Search patterns

If a child or parent component is indicated by its ID in the Excel sheet, the program searches for them with respect to the given search patterns for “.CATPart” and “.CATProduct”.

· If a component is a primary component or standard component (i.e., it is not mentioned as parent in the family tree), the program searches for both corresponding CATProduct and CATPart for it. However, if a corresponding CATProduct is found the CATPart will be ignored.

· If a component is mentioned in the parent column the program searches only for the corresponding CATProduct.

· If several files corresponding the given ID are found, the files with longest file name will be taken by the program. If all files are of the same length, the conventional comparison will determine the result.

The search patterns can be adjusted according to the “wild card” rules of the operating system, in the corresponding items in the dialogue box.

![]()

Figure 4 ‑ 5 Search Patterns for CATPart or CATProduct files

Some examples of search pattern are given in the Table 4‑2 :

Table 4 ‑ 2 CAD File search pattern examples

|

Pattern |

Result |

|

ID

.CATPart |

A file with the name: “

ID.CATPart

”, for example for a given ID of A0050068

the file A0050068.CATPart will be searched for |

|

*ID*.CATPart |

Any file containing the given ID as part of its name

will be searched for |

|

*ID

.CATPart |

Any file name ending with “

ID.CATPart

” will be searched for |

|

ID*.CATPart |

Any file name with extension “CATPart”,

starting with given ID will be searched for |

|

?ID

.CATPart |

Any file name that has only one letter before ID and

ends with “ID.CATPart”

will be searched for |

|

C ID

.CATPart |

Any file name starting with letter “C” followed by “ID.CATPart” will be searched for |

|

CC ID ee.CATPart |

Any file name starting with “CC” then ID then “EE”

then “.CATPart” will be

searched for |

4.1.1.5. Analyse Button

This button runs an analysis on the child-parent relations in order to figure out the family tree, and also checks the existence of the component CAD files. If any problem is detected in the given data a corresponding warning or error is generated. List of the problems checked for is given in the Table 4‑3 :

Table 4 ‑ 3 Problems checked for in the parent-child definition excel sheet

|

Problem |

Type |

Meaning |

|

No Root |

Error |

Could not find the final product in the excel file.

Possibly the product tree root is involved in a loop. |

|

Infinite Loop |

Error |

The analysis detected that the give child-parent

relations is inconsistent so that, some relations definitions lead an invalid

loop (i.e., some parent is mentioned as child of one of its descendants)

The loop is listed in the errors window like this:

“OP45 ! OP

50

!

OP70 ! OP45”

Where a “!” separates the sequence of child

definitions leading to the loop. |

|

Missing Component |

Warning |

A primary component given as child in the Excel sheet

could not be found. As a result, the parent assembly files will be defected.

The list of missing can be seen by opening the errors

window. |

|

File name discrepancy |

Fatal Error |

Different file names are given for the same component

throughput the parent child definitions table |

|

File Type Invalid |

Error |

Parent components may only be of CATProduct

file type. If the given file name is of CATPart

type this error is generated |

|

Folder Invalid |

Error |

If the given folder for a component does not match

the acceptable format of the operating system this error is generated |

|

Invalid Excel file format |

Error |

A row including “child” and “parent” cells could not

be found in the excel sheet to be considered as the table title |

|

Position Components Not Valid |

Fatal Error |

Position input data is not valid so that program could

not parse position components for child |

|

Component Duplicated |

Fatal Error |

A component is placed at the same position in the

assembly file more than once |

|

Property Row Problem |

Warning |

Duplicate values are given for a property of a

component. The duplicated value is ignored. |

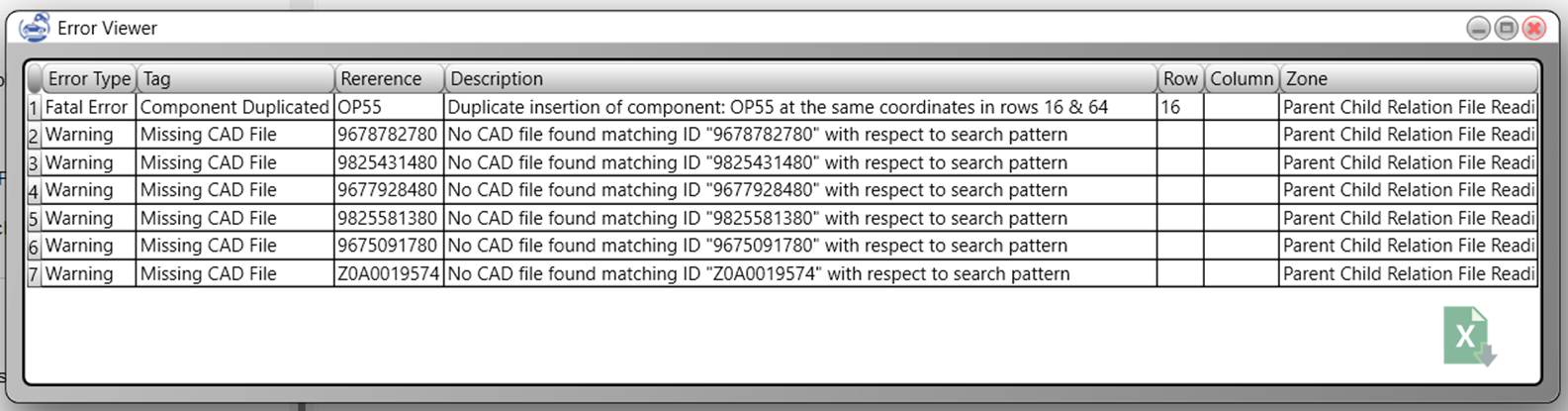

4.1.1.6. Errors Button

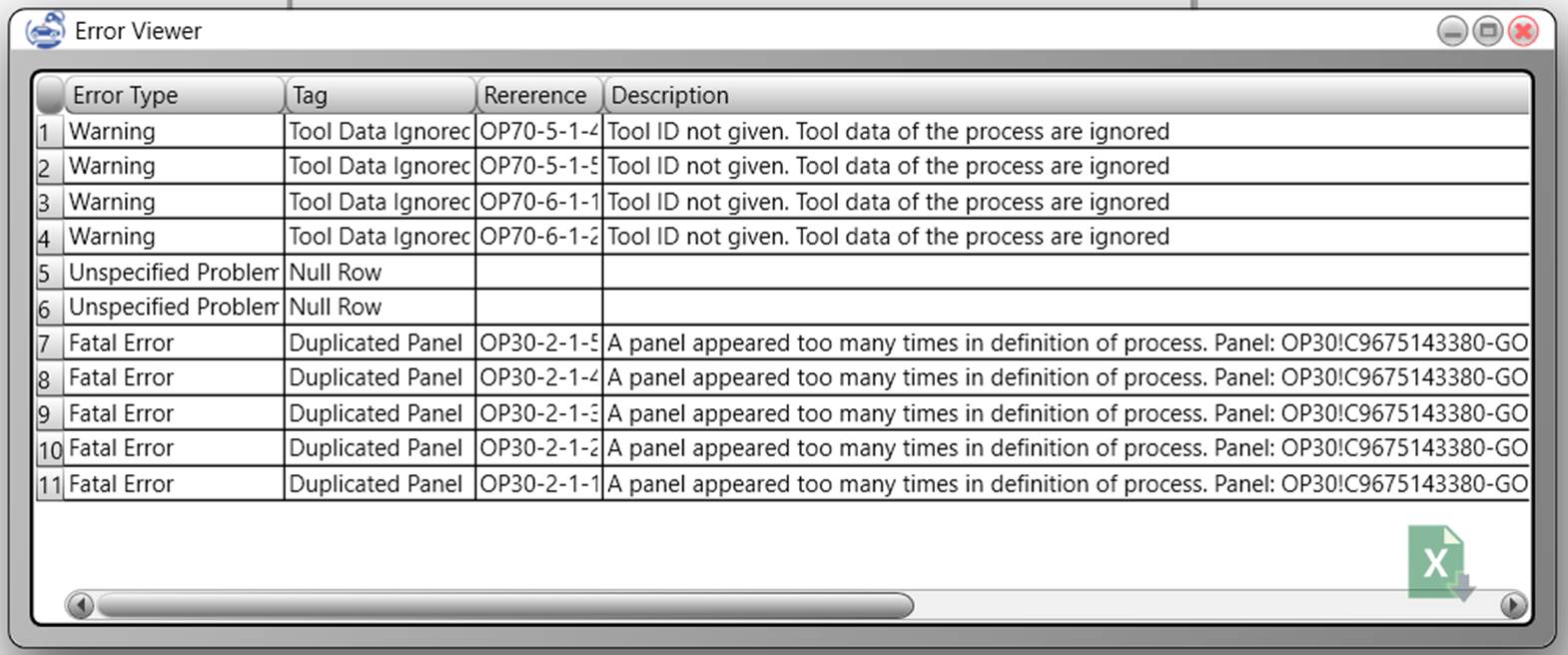

After running the analysis on the input data, if any problem is detected this button is activated and the button text changes to reflect the number of warnings and errors. If any errors are detected the button text color turns red. Clicking on this button opens a window listing the problems. An Example of errors window is shown in Figure 4‑6 .

Figure 4 ‑ 6 Example of errors detected in analysis of Child-Parent relatons Excel sheet

4.1.1.7. Create Project

If no errors are detected after analysis of the input data, this button will be activated. By clicking on the “Create a new project” the new project will be created. If there are any warnings detected in the input data, it’s up to the decision of the user to create a new project with imperfect data or not.

The new project gathers more related information from the project folder, like process drawings and component images if available.

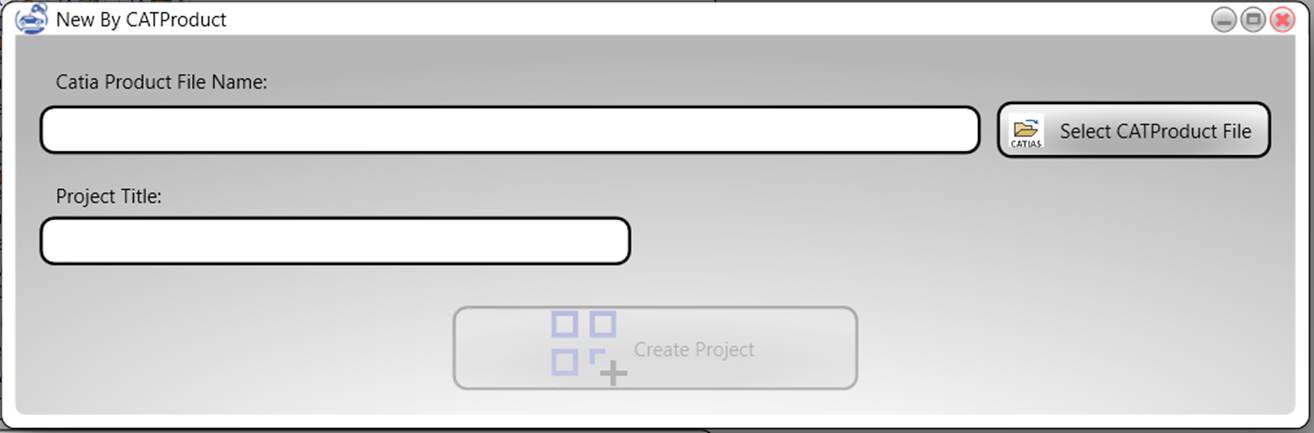

4.1.2. New From CATProduct

If a Catia assembly file constructed according the desired family tree is already available, a new BIW-AP project can be started by extracting the family tree from this CATProduct file. The corresponding command is invoked by the menu path “File > New > By Importing from .CATProduct File”.

Clicking on this menu opens a simple dialogue box for selecting the Catia file and entering the project title. This dialogue box is shown in Figure 4‑7 .

Figure 4 ‑ 7 New by CATProduct dialogue window

By clicking on the create button the new project will be created. If any errors are encountered in creation of the new project a message box prompts for the error and the errors list can be seen in the opening error window.

The new project gathers more related information from the project folder, like process drawings and component images if available.

4.2. Open

By clicking on the open menu

item, a dialogue box pops up for choosing a file with extension BIW-AP. By

choosing the project file the project opens.

The new project gathers more related information from the project folder, like process drawings and component images if available, and updates its own data with the date found in the project folder.

4.3. Save

If the project has

already been saved once this button updates the saved file. And if the file has

not been saved yet it asks for a file name with extension BIW-AP and saves the

project information in it.

4.4. Save as

It opens a dialogue box

to ask a new file name with extension BIW-AP and saves the project in it.

4.5. Exit

This menu item closes the

program. If the current project contains unsaved data or there are running

tasks in the program, it asks for confirmation before exit.

5. Project Menu

Functions for manipulating project data are listed in project menu items.

Figure 5 ‑ 1 Project Menu Items

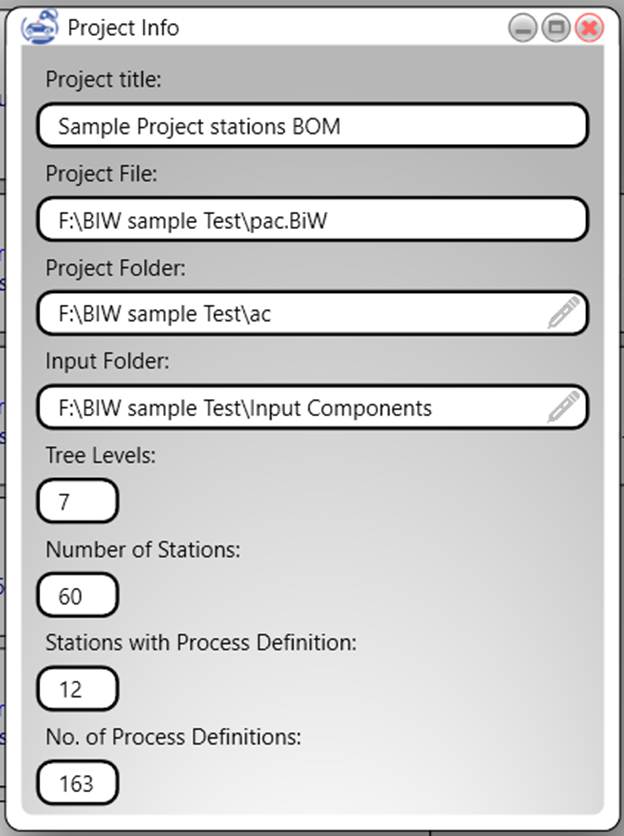

5.1. Project Info

By clicking on project info

menu item, a window opens that shows overall information of the project as

shown in

Figure 5‑2

.

Figure

5

‑

2

Project Info Window

Project title that will

appear in all drawings, can be seen or edited in this window. Project input

folder and output folder addresses are also listed in this window. These folder

addresses can be changed by clicking on the pencil icon on right side of the

folder address text boxes. By choosing a new folder, the project checks for availability

of files in the new folders and updates the project info with the new folder.

5.2. Data tree Viewer

This opens a new window

which provides visualization of the project family tree with the same

capabilities as the data view area of the main window explained in

3.2.1

. This menu item is useful for cases we would like

to work or watch different branches of the family tree at the same time. As many as wished data tree viewers can be

opened if required.

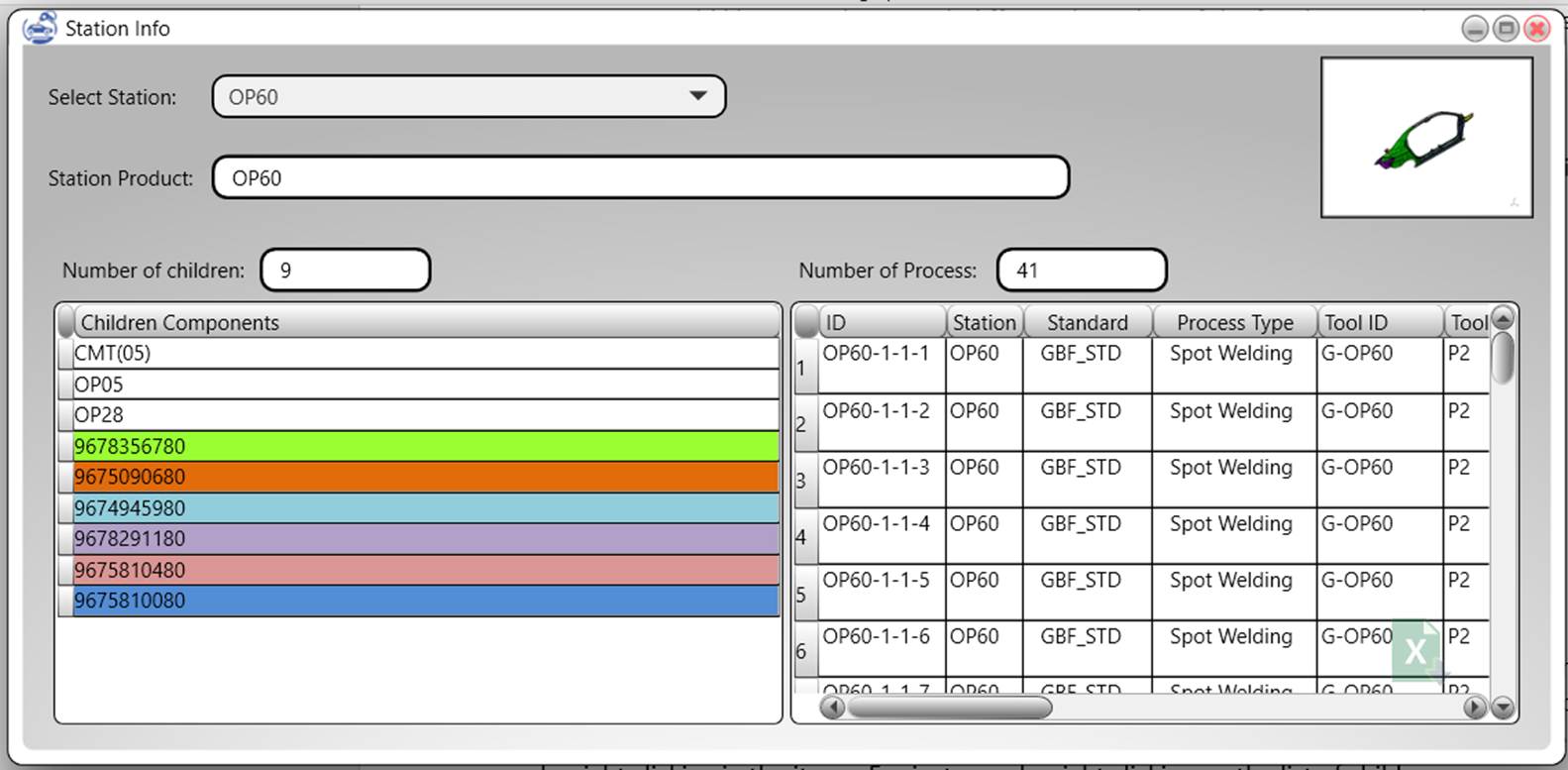

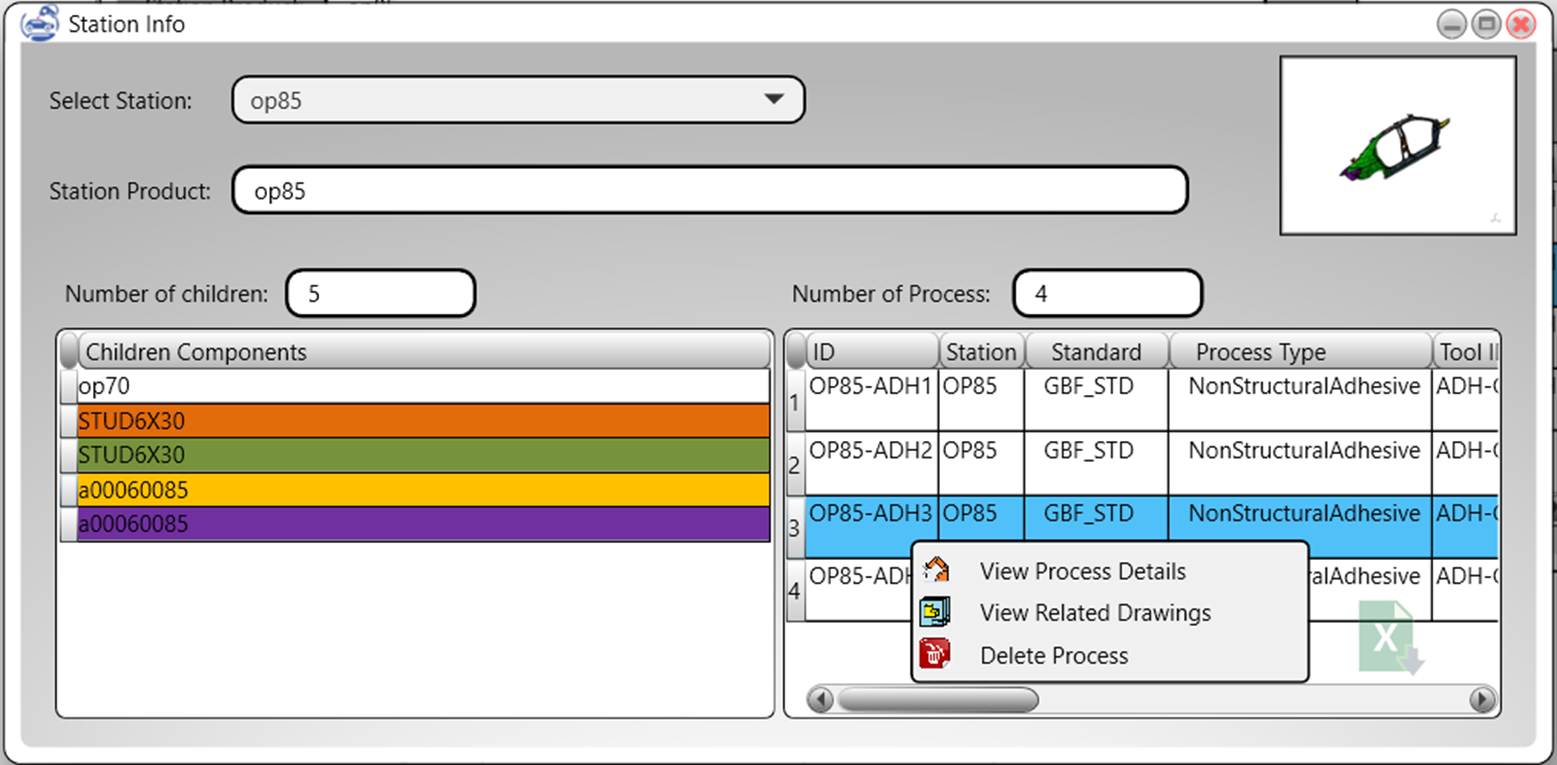

5.3. stations

This menu item opens a

station viewer window in which an overview of information of stations defined

in the project, are shown.

Figure

5

‑

3

Station Viewer

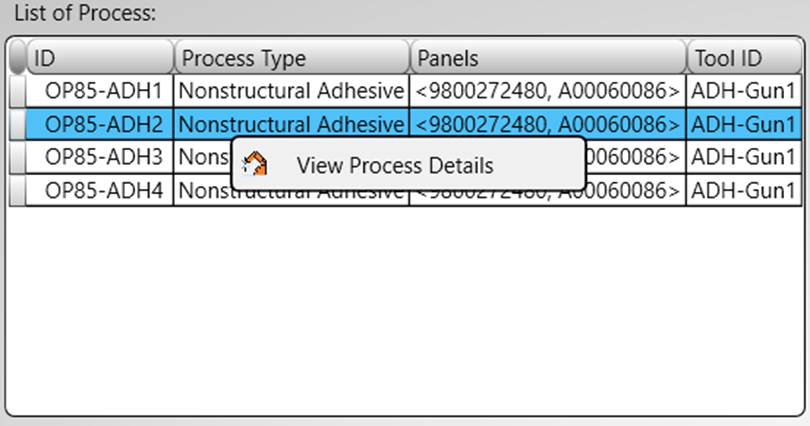

The station viewer window

gives the information about component created in the station including the station

type, file name and component name, list of children components, tools and list

of process definitions. More details of functions available for each of shown

items in the station viewer can be seen by right clicking in the items. For

instance, by right clicking on the list of children components a pop-up menu

opens with the option of seeing details of the component. Or, by right clicking

on the process list the details of each process can be seen.

5.4. Create assembly files

If the assembly files are

not already created, they can be creating through this menu item. If Catia

program is not running on the computer a message box will prompt the user to

run Catia and try again. This function also creates an image of all component

in the family tree.

During creation of the

assembly files and images, Catia remains hidden. However, the progress is shown

in the status bar area. Also, in the data view area, the status of each

corresponding node will change to a green text of “File Created”. Image of each

component appears on the left side of the corresponding bubble immediately

after creation.

5.5. Create Images

This menu item creates an

image for all components in the family tree which have existing CAD files. Each

created image appears on the left side of the corresponding bubble immediately

after creation. The images are also used in creation of the family tree chart

in Excel. The images are created in a subfolder named “Images” in the project

folder.

5.6. Change Project Folder

This menu item allows to

choose a new folder as the project folder. By choosing a new folder, the

project checks for availability of files in the new folders and updates the

project info with the new folder. This option a provides the possibility of

moving the project folder to a different drive or folder on the computer or

working on the same project in different computers.

5.7. Relocate Input Folder

This menu item allows to

choose a new folder as the input folder. By choosing a new folder, the project

checks for availability of files in the new folders and updates the project

info with the new folder This option a provides the possibility of moving the

input folder to a different drive or folder on the computer or working on the

same project in different computers.

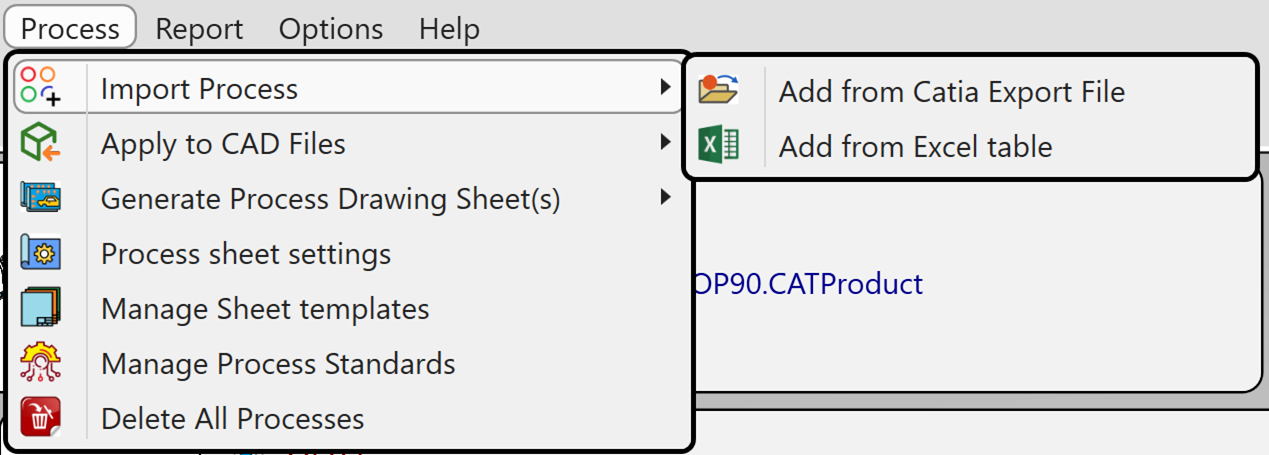

6.

Process Menu

This menu provides

functions for defining or modifying BiW processes

jobs to the project information, adding the process information to CAD files

and creation of technical shop drawings for processes.

Figure

6

‑

1

Process Menu

6.1. Import Process

This meu item opens a sub menu providing two methods for importing process definitions into the project data. The “Add from Catia Export File” option allows to import the process definitions from BiW Fastening process definitions in a CATProduct file.

The “Add from Excel table” option allows to import process definition from an Excel sheet. This option uses the advantage of the flexibility of MS Excel sheets to import process definitions from any kind of process definition data base or process definition banks. All required task is to export the process data from process definition bank to an Excel sheet and modify the sheet according to the data format of the BIW-AP process definition table.

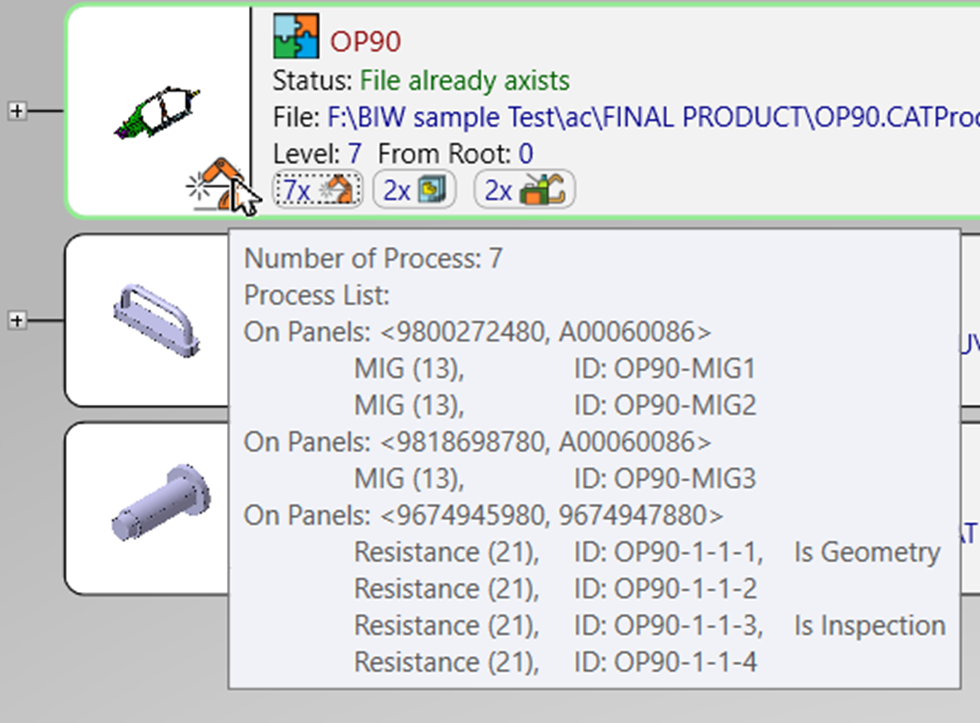

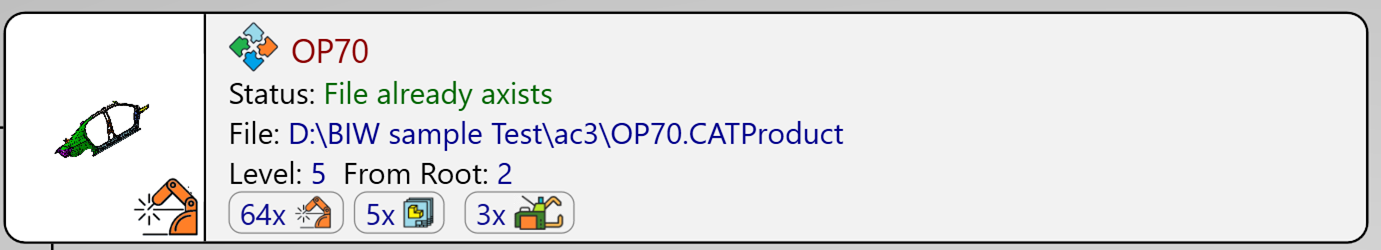

After importing processes, an icon of process (

![]() )

appears on the bottom right corner of the image area of the tree node bubble

for stations in which process definitions were imported. By keeping mouse over

this icon for moment, a tooltip bubble pops up in which a brief report of the

process definitions in the station is listed. As shown in

Figure 6‑2

.

)

appears on the bottom right corner of the image area of the tree node bubble

for stations in which process definitions were imported. By keeping mouse over

this icon for moment, a tooltip bubble pops up in which a brief report of the

process definitions in the station is listed. As shown in

Figure 6‑2

.

Figure 6 ‑ 2 Process icon and the brief report of process definitions in the staion

Also, two small buttons appear on lower edge of the station info area, which show the number of process and tool definitions in the station ( Figure 6‑3 ). A click on these buttons respectively opens a process list window or tool list window.

![]()

Figure 6 ‑ 3 Processes, Drawings and Tools List Buttons on station info bubble

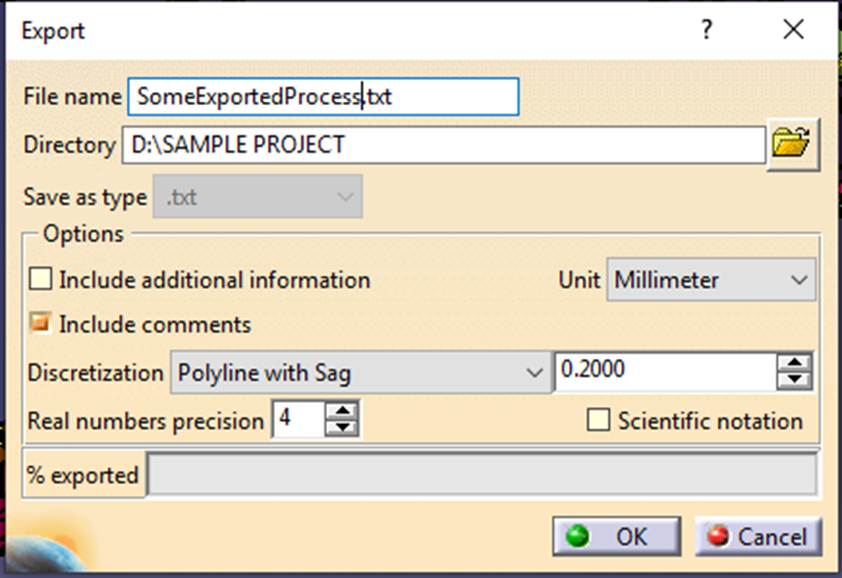

6.1.1. Import From Catia BiW Fastening

In order to import

process definition from BiW Fastenings in a CATProduct file, the process definitions should be exported

to a text file using export tool in BiW Fastening

module of Catia. The export tool opens a dialogue box in which the user can

assign a file name and indicate the directory in which the export file will be

created. The check box of “Include additional information” should be unchecked

in this dialogue box.

Figure

6

‑

4

Automotive BiW Fastening

export dialog box in catia

After successfully

exporting the BiW Fastening definitions in to a text

file. The user can import the process definitions in to BIW-AP project by

clicking on the “Add from Catia Export File” menu item. The program asks for

the import file and imports the process definitions to the corresponding

station data.

Note:

Uncheck the “Include additional information”

check box.

6.1.2. Import From Excel file

By clicking on this menu

item, the program opens a dialogue box asking for the excel file of process

definitions. The program then reads the excel file and incorporates the process

definitions to the station definitions of the project.

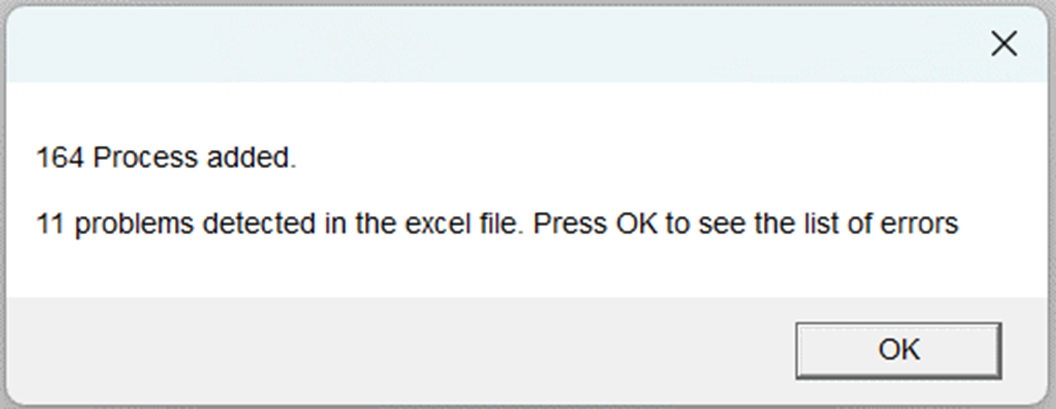

Each row of process

definition in the excel sheet is investigated separately by the program and if

there is no problem in the definition, the process is added to the project

information. Therefore, if there are problems in only some of the process

definitions in the excel file, they do not affect the correct process

definitions and the excel sheet is incorporated partially to the program

information. The program prompts about the number of correctly incorporated

process definition and the number of erroneous rows in the excel sheet as shown

in

Figure 6‑5

.

Figure 6 ‑ 5 The program prompt on result of process definition reading from Excel sheet

If any problem is

detected in the process definitions the program opens a report window listing a

report of the detected problems as shown in

Figure 6‑6

.

Figure

6

‑

6

Error report of importing process

from Excel file

6.1.3. Process Excel File Format

In order to import data from Excel the process information should be written in a table in the first worksheet of an Excel file with a specific format. The table format contains two rows of table title. The first row of table title holds the main column titles and the second row holds subtitles or default values. The table should contain four mandatory titled columns, but there are several optional table columns that can be added to the table for additional information.

The mandatory titles are listed in Table 6‑1 :

Table 6 ‑ 1 mandatory titles of Process definition table

|

Title |

Meaning |

|

Process/Spot ID |

Each process definition should have a unique

identifier that can be a text, number, or specific characters or combination

of them |

|

Station ID |

The ID of the station in which the process will be

applied on the BiW panels |

|

Panel 1 |

At least one panel is required for definition of a

process, however most of process types usually are applied on a couple of

panels or more. So, definition of a column titled “Panel 1” is mandatory

however more panels can be defined for process by adding columns of “Panel

2”, “Panel 3”, … and so on. |

|

Position(s) |

The X,Y,Z coordinates of

each process. |

In addition to the mandatory columns, some arbitrary can be defined in the process definition tables as listed in Table 6‑2 .

Table 6 ‑ 2 Arbitrary titles of the process definition table

|

Title |

Default Value |

Meaning |

|

Standard |

GBF_STD |

Name of the BiW Fastening standard

definition corresponding to that of Catia |

|

Process Type |

Unspecified |

Type of the process as defined in the standard |

|

Spot Diameter |

4.0 |

Diameter of spot-weldings

or thickness of weldings or other types of process

definitions |

|

Flags |

- |

Flags of a process definitions like Geometry,

Inspection etc. |

|

Tool ID |

- |

ID of the tool assigned for application of the

process |

|

Tool Generic Name |

- |

Generic name of the tool type like welding gun,

welding torch etc. |

|

Tool Generic Type |

- |

Generic type of the tool like X or C for spot welding

guns |

|

Tool Manufacturer |

- |

Manufacturer name or info of the tool |

|

Tool Manufacturer Type Code |

- |

Type Code of the tool in manufacturer standards |

|

Tool Program |

- |

Program ID of the tool for the process |

|

Tool Location Code |

- |

Location of the tool in the factory |

Note: Each table title may include several subtitles in the subtitle row. I case there are more than one subtitle for a table title, the title cell is a merged cell merging the title cells of all subtitle columns.

6.1.3.1. Process/Spot ID

The Process/Spot ID column comprises a single excel sheet column and takes no value in the subtitle row. The IDs of the processes are entered in this column and there is no specific rule for definition of the process IDs. The Process IDs can be a combination of alphabet characters, numbers and special characters. The only rule in this column is that the IDs should be unique.

Note: Please note that the process IDs are CASE SENSITIVE. This means that the program differentiates between capital letters and small letters.

6.1.3.2. Station ID

The station ID should be corresponding to ID of a station already defined in the family tree of the project.

6.1.3.3. Panel

Each Panel column comprises three sub columns with subtitles of “ID/Code”, “Name” and “Thickness”. One of either “ID/Code” or “Name” values is mandatory for definition of a panel. However, the priority is with “ID/Code”. This means if the ID of a panel is given the program ignores the name of the panel.

The given ID should correspond to the ID of a component in the family tree of the project. The “Name” of the panel should correspond to the “Part Number” in the CATPart file of a component in the family tree of the project.

Note: Please note that the “Part Number” of a Catia part is different from the file name. So, it should be carefully extracted from CATPart file by opening the CAD file in Catia and finding the “Part Number” on the root of tree structure or inside the “properties” dialogue box.

Note: if a panel appears more than once in the product tree structure of a component, i.e., in case the panel is a standard component or part of a subassembly repeatedly inserted into the product, definition of the panel requires resolving the ambiguity of the panel under process. By default, the program automatically resolves the ambiguity by finding the instance of panel coinciding with the process position. However, there is an option for explicitly specifying the intended panel in the excel file. The ambiguity resolving is explained in section 6.1.3.4 .

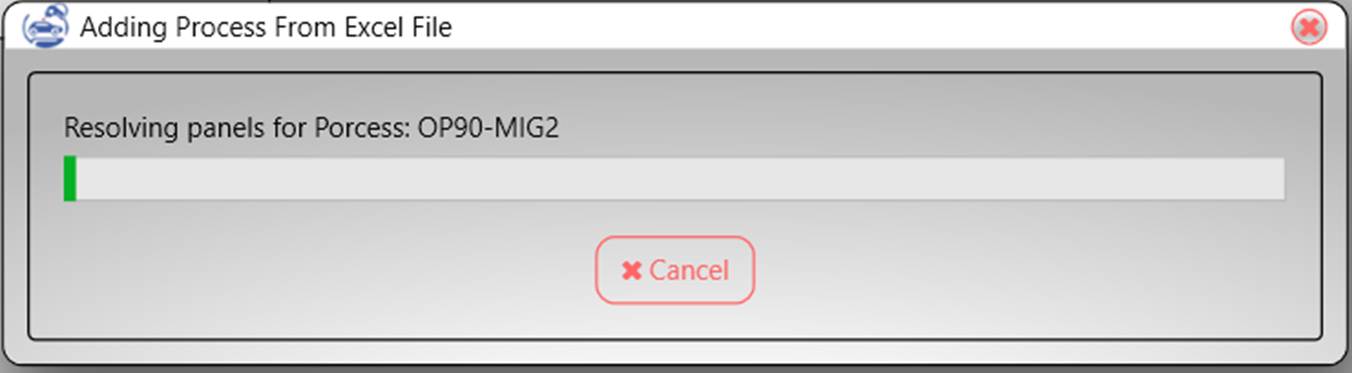

6.1.3.4. Resolving Panel Ambiguity

If a panel appears more than once in the product tree structure of a component, i.e., in case the panel is a standard component or part of a subassembly repeatedly inserted into the product, definition of the panel requires resolving the ambiguity of the under-process panel. By default, the program automatically resolves the ambiguity by finding the instance of panel coinciding with the process position. However, there is an option for explicitly specifying the intended panel in the excel file.

Automatic resolving panel ambiguities

By default, the program automatically resolves the ambiguity by finding the instance of panel coinciding with the process position. In order to resolve the ambiguity, the program first measures the distance of the process location and all instances of the ambiguous panel in the station. The closest panel is then selected as the target of the process.

The panel resolving procedure is a relatively time taking procedure. The program exploits Catia for measuring the distances. Specially in large products the measurements take more time and CPU load. As a rough estimate, in a complete car body model it may take up to two minutes to resolve panel ambiguities for each process definition.

During running of ambiguity resolving, a progress window appears on the screen, showing the progress status in a progress bar. A cancel button on the progress window allows cancelation of the procedure. During execution of the panel resolving functions, the program seems irresponsive due to the heavy CPU usage of CATIA. Therefore, after clicking on the cancel button, please be patient for a minute until after finishing measurements of the current process program responds to your command and cancels the procedure.

Figure 6 ‑ 7 Panel ambiguity resolving progress window

Regarding the time taking procedure of the automatic panel resolving, an alternative option is available to manually identify the target instances for ambiguous panels, by providing an address clue in the definition of panels in the process definition excel sheets.

Address Clue

Regarding the time taking procedure of the automatic panel

resolving, an alternative option is available to manually identify the target

instances for ambiguous panels, by providing an address clue in the definition

of panels in the process definition excel sheets. If the option of “Prefer

Resolving Panel Ambiguity by Address Clue” in checked in the project options

(See

8.1.6.1

), the program first looks for address clues in panel definitions and uses the

given address clues for resolving ambiguity of the corresponding panels. The

address clue can be added before panel name in the panel name column of the

excel sheet.

The address of the panel,

relative to the station in which the process is defined, comprises the sequence

of tree nodes starting from the station product down to the intended panel. The

address starts with the “Part number” of the station, then an exclamation sign

(i.e., “!”), then the “instance name” of the subsequent node (usually the part

number of the node with a trailing “.1”, “.2” etc. in Catia), then an

exclamation sign, then the instance name and an exclamation sign for the next

node and so on, down to the intended panel’s “instance name”. The panel “Part

Number” should come after the address clue. Below, some examples of panel

address clue definitions are given.

Table 6 ‑ 3 Some examples of address clue definition

|

OP85.1!A00060085-LOCKU.1!A00060086-BAS.1!A00060086-BAS |

|

OP85.1!A00060085-LOCKU.2!A00060086-BAS.1!A00060086-BAS |

|

OP55.1!A00060085-LOCKU.1!A00060086-BAS.1!A00060086-BAS |

Note:

If ambiguous panels have common sequence of nodes

in starting part of their address, the common part of their address can be

ignored. In other words, the minimum address information that clarifies the

ambiguity if enough for definition of the address clue.

6.1.3.5.

Position(s)

The “position(s)” table column

accommodates the place for insertion of X, Y and Z coordinates of as many

points as required for definition of the process. The subtitle row of the

position(s) includes repeated sequences of three columns for X, Y and Z

respectively. For definition of processes that apply to a single spot (i.e.,

spot welding, riveting, clinching etc.) only a single set of X, Y and Z can be

given whereas for processes that apply on curves, such as MIG Welding, a

multitude of at least two sets of X, Y and Z coordinates are required.

6.1.3.6.

Standard

The standard column is

optional. If the table does not contain a standard column the standard of the

process is set to “GBF_STD”, which is equivalent to the default BiW Fastenings standard in Catia.

The default standard of

Catia BiW Fastenings module is predefined in the

program under name of “GBF_STD” with the default process types as those of

default “GBF_STD” standard of Catia. If the BiW

Fastenings standard in Catia is customized or new standards are defined in

Catia, the equivalent standard can be defined or edited in the BiW-AP as explained in sec

6.6

.

6.1.3.7.

Process Type

The “process type” column

is an optional column. In case no process type column is given in the table,

all processes take the first type defined in the standard (“Unspecified” in

case of default standard of “GBF_STD”). If the process type column is added to

the table, a default value can be defined in the subtitle row for the process

type, so that all the process definitions with a blank cell take this default

value.

The predefined process

types in the default “GBF_STD” in the program are listed in table below:

Table 6 ‑ 4 Predefined Process Type Definitions

|

|

Name

|

Acro

|

CATIA

PTYP Name

|

Spot Operation

|

Curve Operation

|

|

1 |

Unspecified 1 |

U1 |

Unspecified 1 |

Spot Defined |

Curve Defined |

|

2 |

Unspecified 2 |

U2 |

Unspecified 2 |

Spot Defined |

Curve Defined |

|

3 |

Spot Welding |

SPW |

Resistance Welding |

Spot Defined |

N/A |

|

4 |

Resistance Welding |

RES |

Resistance Welding |

Spot Defined |

Curve Defined |

|

5 |

TIG |

TIG |

TIG |

Spot Defined |

Curve Defined |

|

6 |

TIG (14) |

TIG14 |

TIG (14) |

Spot Defined |

Curve Defined |

|

7 |

TIG (141) |

TIG141 |

TIG (141) |

Spot Defined |

Curve Defined |

|

8 |

Laser |

LAS |

Laser |

Spot Defined |

Curve Defined |

|

9 |

Unspecified Welding |

UNSW |

Unspecified Welding |

Spot Defined |

Curve Defined |

|

10 |

MIG |

MIG |

MIG |

N/A |

Curve Defined |

|

11 |

MIG (13) |

MIG13 |

MIG (13) |

N/A |

Curve Defined |

|

12 |

MIG (131) |

MIG131 |

MIG (131) |

N/A |

Curve Defined |

|

13 |

Roll Seam |

RSM |

Roll Seam |

N/A |

Curve Defined |

|

14 |

Flash Butt |

FBT |

Flash Butt |

N/A |

Curve Defined |

|

15 |

Resistance Butt |

RBT |

Resistance Butt |

N/A |

Curve Defined |

|

16 |

Brazing |

BRZ |

Brazing |

N/A |

Curve Defined |

|

17 |

Projection |

RPRJ |

Projection Resistance |

Spot Defined |

N/A |

|

18 |

Unspecified Projection |

UPRJ |

Unspecified Projection |

Spot Defined |

N/A |

|

19 |

Clinching Point 1 |

CLI |

Clinching Point |

Spot Defined |

N/A |

|

20 |

Clinching Point 2 |

CLI2 |

Clinching Point 2 |

Spot Defined |

N/A |

|

21 |

Rivet |

RVT |

Rivet |

Spot Defined |

N/A |

|

22 |

Unspecified BiW Mechanical

|

UNSM |

Unspecified BiW Mechanical

|

Spot Defined |

N/A |

|

23 |

Punch Rivet |

PR |

Punch Rivet |

Spot Defined |

N/A |

|

24 |

Blind Rivet |

BR |

Blind Rivet |

Spot Defined |

N/A |

|

25 |

Robot Sealant |

ROS |

Robot Sealant |

Spot Defined |

Curve Defined |

|

26 |

Manual Sealant |

MAS |

Manual Sealant |

Spot Defined |

Curve Defined |

|

27 |

Unspecified Sealant |

UNSS |

Unspecified Sealant |

Spot Defined |

Curve Defined |

|

28 |

Structural Adhesive |

STR |

Structural Adhesive |

Spot Defined |

Curve Defined |

|

29 |

Nonstructural Adhesive |

NSTR |

Non

Structural

Adhesive |

Spot Defined |

Curve Defined |

|

30 |

Unspecified Adhesive |

UNSA |

Unspecified Adhesive |

Spot Defined |

Curve Defined |

Either of Name, Acro or

Catia PTYP Name of the process type may be used for defining process types. The

spot and curve operation columns indicate the possibility of definition of the

process on curves or spots. For definition of process on curves, it is

necessary to define at least two sets of coordinates in the position columns.

6.1.3.8.

Diameter

A “diameter” column can

be added for defining a diameter for spot operations of thickness for curve

operations. A “default value” can be defined in the subtitle of this column. If

the table is missing the diameter column all the processes take a diameter

value of “3”.

6.1.3.9.

Flags

The “Flags” table title

may accommodate any number of sub columns for definition of flags for the

process. The “Is Geometry” and “Is Inspection” values are considered as

preserved words for flags which are specially treated in the program as

standard indications. Beside these two, any text or note can be given as flag

for the process.

6.1.3.10.

Tool Definition

Several optional titles may be added to the table for definition of tools. These titles include “Tool ID”, “Tool Generic Name”, “Tool Generic Type”, “Tool Manufacturer”, “Tool Manufacturer Type Code”, “Tool Program”, “Tool Location Code”.

Tool id

Tool ID is mandatory for definition

of tool for a process.

Tool Generic Name

Definition of the tool

generic name is optional and a default value can be defined for it in the

subtitle row. For a specific tool (i.e., a specific tool ID), it is enough to

define the tool generic name only once in the table.

Tool Generic Type

Definition of the tool

generic type is optional and a default value can be defined for it in the

subtitle row. For a specific tool (i.e., a specific tool ID), it is enough to

define the tool generic type only once in the table.

Tool Manufacturer

Definition of the tool manufacturer

is optional and a default value can be defined for it in the subtitle row.

For a specific tool (i.e., a specific tool ID), it is enough to define the tool

manufacturer of each tool only once in the table.

Tool Location Code

Definition of the tool location code

is optional and a default value can be defined for it in the subtitle row.

For a specific tool (i.e., a specific tool ID), it is enough to define the tool

location code of each tool only once in the table.

6.1.3.11. Tool Program

Tool program is a property attributed to the process definition. A specific tool may be used with different programs for several processes. The tool program may be a number a text of combination of numbers and text. Default value may not be defined for tool program in the table.

6.2. Apply to CAD Files

This menu provides two methods for applying the process definitions into CAD files. The first method is to add the processes as BiW Fastenings to the CAD files. This method creates BiW Fastening entities as provided in BiW Fastenings workbench of Catia. For more information about BiW Fastenings in Catia you may refer to the official help documents of Catia.

The second method for applying processes to the CAD files, creates spherical or worm shapes in Catia corresponding to spot or curve processes respectively.

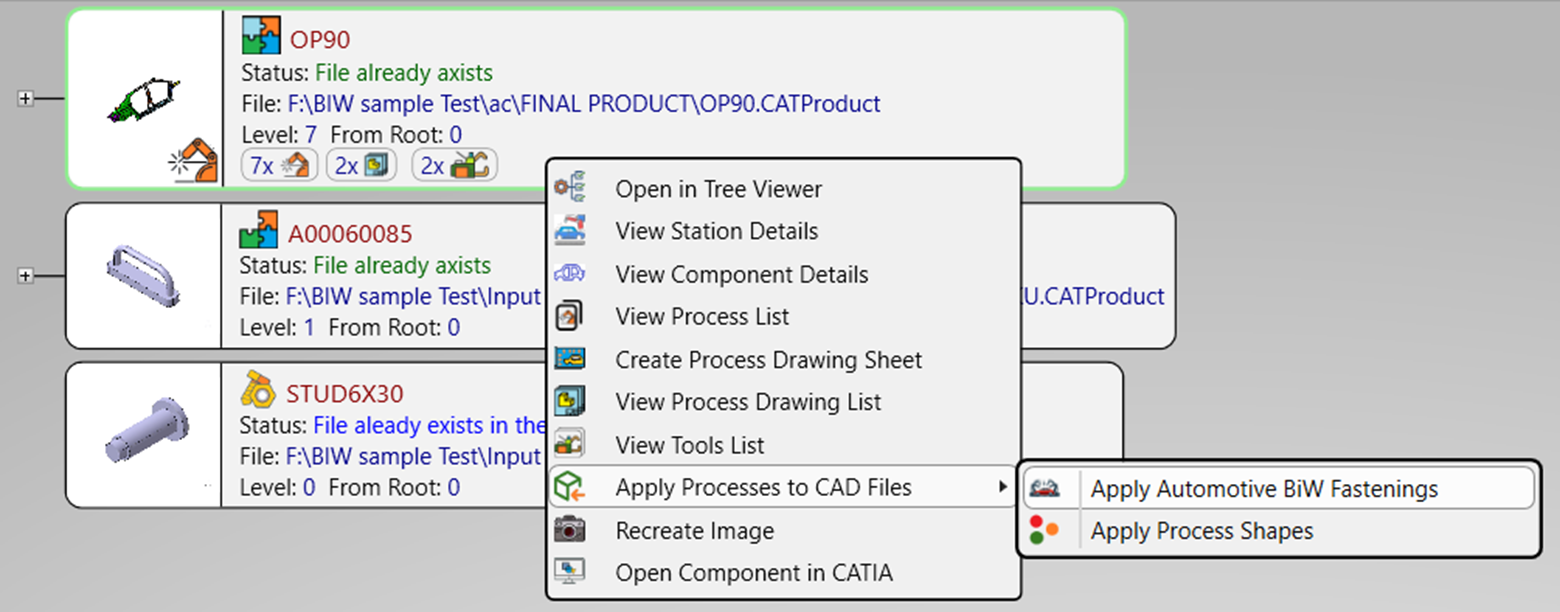

6.2.1. Create BiW Fastenings

This menu item applies BiW fastening entities in Catia files corresponding to all stations with process definition in the project. Alternatively, it is possible to apply BiW fastenings to a specific station by right clicking on the corresponding node in the data tree view of the project and choosing “Apply Process to CAD Files -> Apply Automotive BiW Fastenings”, item in the opened pop-up menu.

Figure

6

‑

8

Apply Proceess to CAD Files Through

Context Menu

6.2.1.1. Create BiW Fastening Options

Options for creation of BiW Fastenings are available in the “Process to CAD Options” tab of the options window. Shown in Figure 6‑9 . (Accessible through menu path “Options -> Settings”)

Figure 6 ‑ 9 Apply to CAD Files Options

The options include:

Only create export files

If this option is not checked, the program creates the BiW Fastenings in the Catia files, however, if this option is checked the program creates process export text file of the process definitions for each station. These export files can be imported into Catia files of the CATProduct file of station component by user.

More information about options of this page is available in section 8.1.5 .

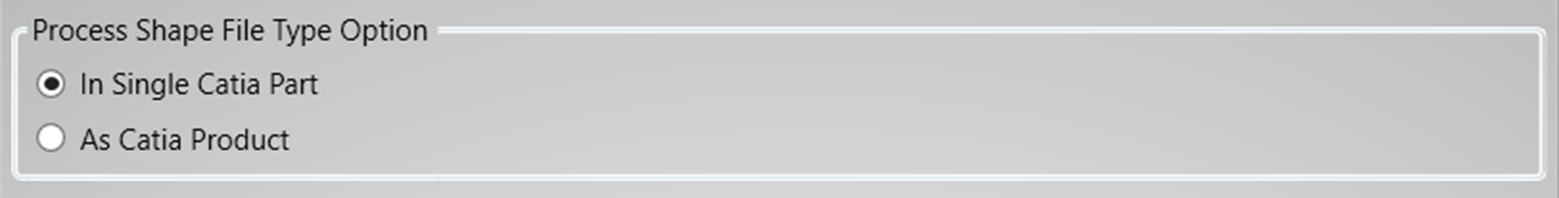

6.2.2. Apply Balls and Shapes

This menu item creates a ball shape for each spot processes and a worm shape along the curve path for each curved process. This menu item creates shapes in Catia files corresponding to all stations with process definition in the project. Alternatively, it is possible to apply process shapes to a specific station by right clicking on the corresponding node in the data tree view of the project and choosing “Apply Process to CAD -> Apply Process Shapes”, item in the opened pop-up menu ( Figure 6‑8 ).

There are two options of file type for creation of the shapes which are selectable in the options window ( Figure 6‑10 ). In the default and first method (i.e., “In Single Catia Part”), all the process shapes of a station are created in a CATPart file and each process shape is created as a body in the created CATPart file with the same name as the process ID. In the second method (i.e., “As Catia Product”), each process shape is created in an individual CADPart file and a CATProduct is also created to accommodate the process shape CATParts.

Figure 6 ‑ 10 Proess Shape File Type Options

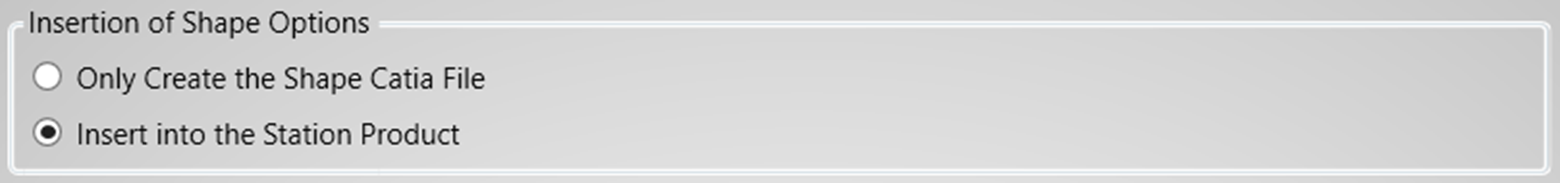

Two options are also selectable for “Insertion of Shapes”, shown in Figure 6‑11 . If The option of “Only Create the Shape Catia File” is selected the Catia file for the shapes are created but are not inserted to the station product CAD files, whereas the option “Insert into the Station Product” inserts the process shape files into the station product CAD file.

Figure 6 ‑ 11 Insertion of Shape Options

More information about options of this page is available in section 8.1.5 .

6.3. Generate Drawing Sheet(s)

This menu item opens a dialogue box for creation of process sheets of the stations. Alternatively, the process sheet creation dialogue box is also available through right clicking on a station in the tree nodes in the data tree viewer for a specific station.

6.3.1.

Process Sheet Creation

Dialogue Box

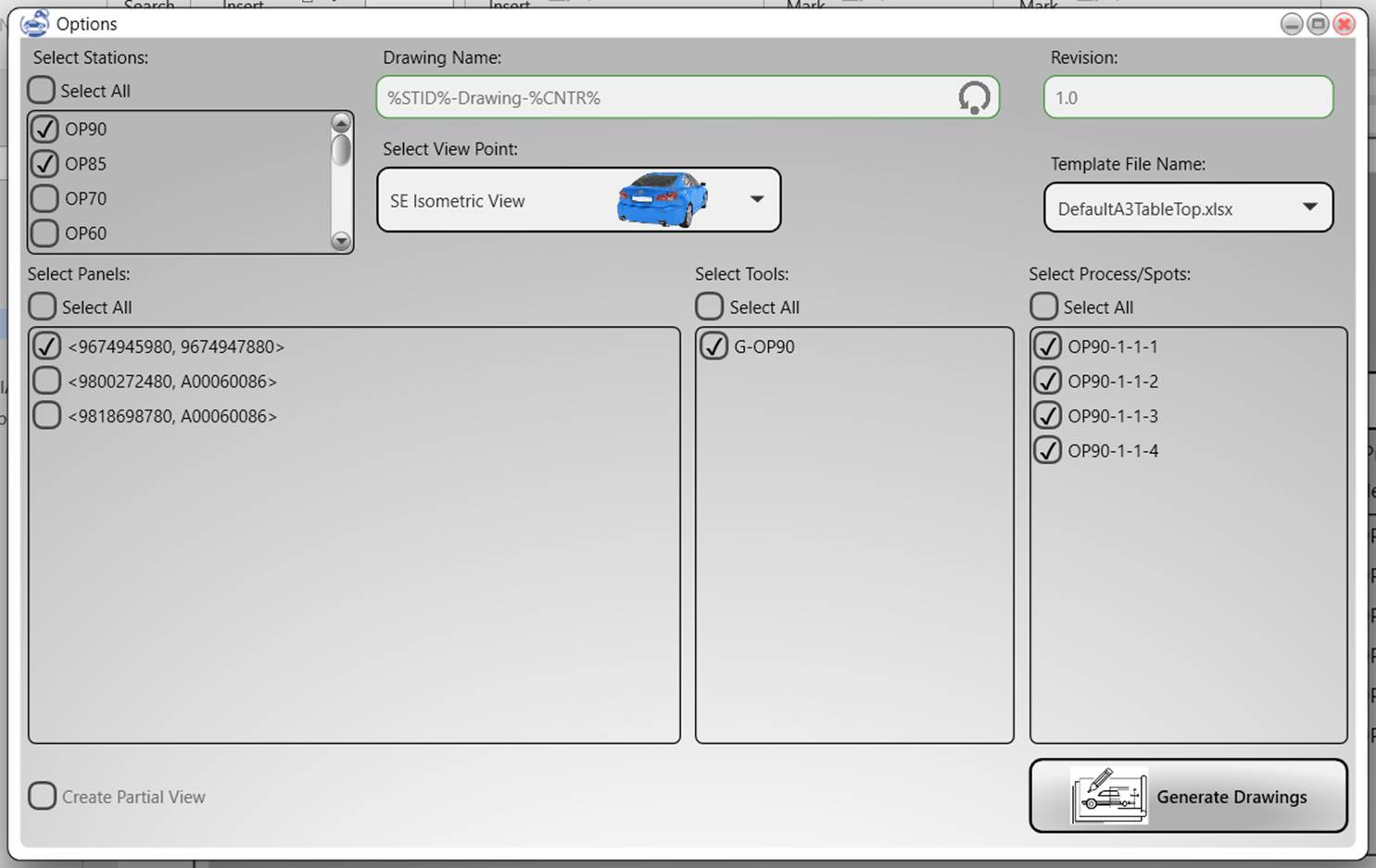

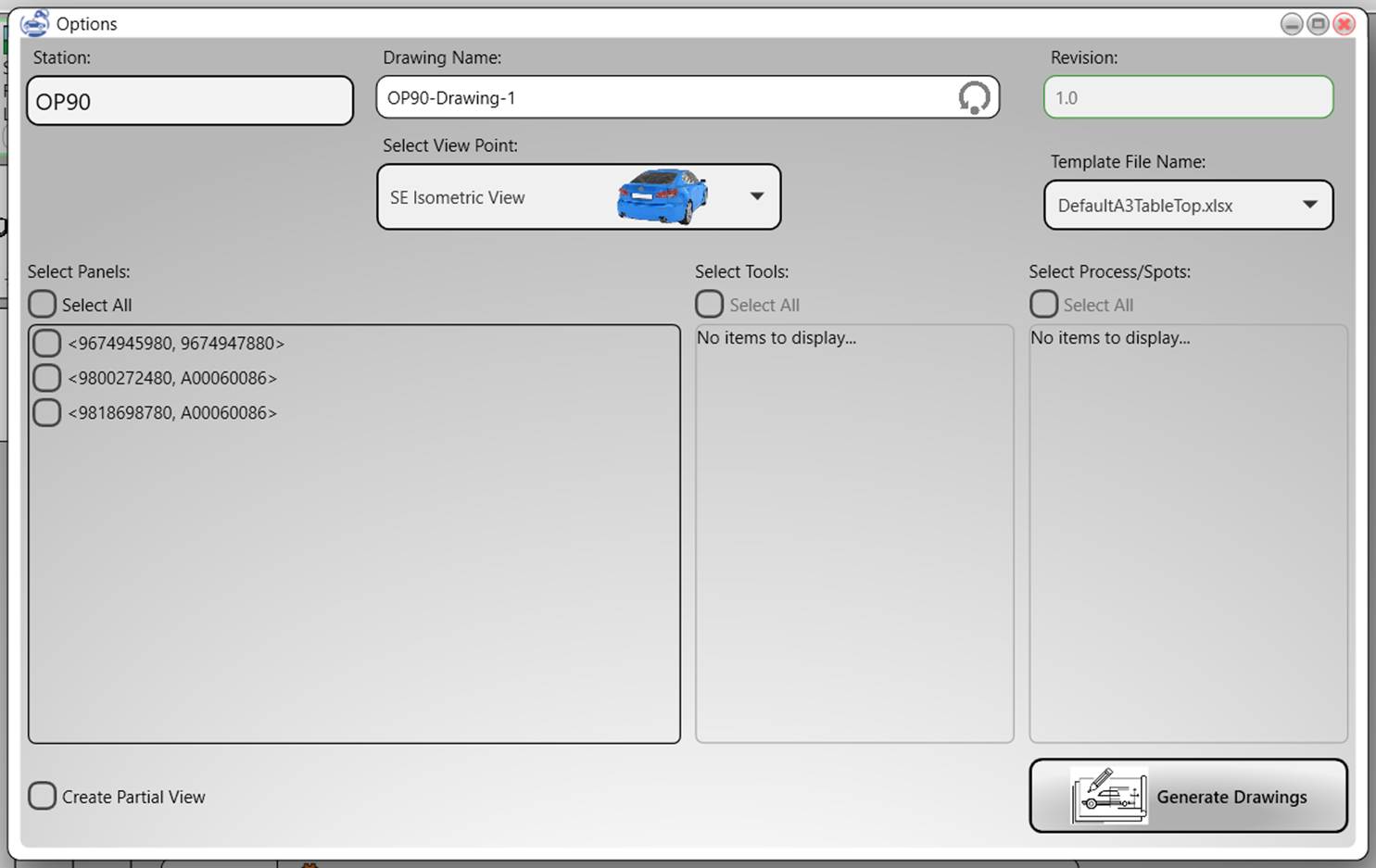

Process sheet creation

dialog is in two slightly different form depending on if it is opened for

creation of drawings for a single station (i.e., when called through the

context menu by right click on a station node in tree view or by click on the

icon in the toolbar), or if it is opened for batch creation of drawings on

multiple stations (i.e., when called through main menu). The two different

forms of the PSC dialog box are shown in

Figure 6‑12

and

Figure 6‑13

.

Figure 6 ‑ 12 Process Sheet Creation Dialogue Box for Multiple Station

Figure

6

‑

13

Process Sheet Creation Dialog Box

for Single Station

The differences in the

dialog boxes include the station selection pane which is not available in the

single station dialog box.

6.3.1.1.

Drawing Name

The drawing name can be

entered or edited in the drawing name text box. If a drawing is being created

for the first time a default drawing name is assigned automatically by the

program for the drawing. However, the user can modify or change this default

auto generated drawing name. The drawing name should be unique and if an

already existing drawing name is entered, a warning message appears above it

and the program will not create the drawing until a valid drawing name is

entered. The changes in the drawing name can be reset by clicking on the icon

button,

![]() ,

on the right side of the drawing name text box.

,

on the right side of the drawing name text box.

The default

auto-generated drawing name is generated according to the drawing name template

that can be managed in the options window (see section

8.1.3.1

).

If a drawing is

regenerated for a new revision, the drawing name is set equal to its name and

is not editable by user.

6.3.1.2.

Revision

Revision of the drawing

is shown in the revision text box. The Revision is set to 1 the first time a

drawing is created. Each time a drawing is regenerated the revision of the

regenerated drawing is incremented by one.

6.3.1.3.

Selection of stations

On the top left corner of the process sheet creation dialogue box (PSC Dialogue) there is a check box list of station with process definitions. The station or stations for which it is intended to create the process sheet can be selected from this list. A select all check box is also available above the list that simplifies selection of all stations for batch creation of process drawing sheets. In case the PSC dialogue box is called through pop up menu in the project tree view, the station ID of the intended station appears in place of the station selection list.

6.3.1.4. Selection by Panel (Pairs)

After selection of stations, a check box list of panels or panel pairs for which there are process definitions in the selected stations appears on the left side of the PSC dialogue box. This list allows filter out the process definitions with respect to their affected panels. A select all check box is available above the list in case filtering out the process definitions by panels is not intended.

6.3.1.5. Selection By Tool

A list of tools assigned to the selected processes is given in the PSC dialogue window. This list allows to filter out process definitions with respect to their assigned tools. By checking the select all check box above this list the filtration by tool is bypassed.

6.3.1.6. Selection by Process ID

The list of process IDs after passing the filters of station, panel and tool sections is given in this area of the PSC dialogue box. The desired process IDs can be selected by checking the corresponding check box. The select all check box above the lost allows to select all the listed processes.

6.3.1.7.

Sheet Template Selection

The sheet template

selection combo provides a list of available sheet templates for selection. A

blank sheet and several default sheet templates are available as out of the box

companions of the program. The default sheet templates are available for A4, A3

and A2 drawing paper sizes. The tables of the default sheet templates provide

place holders for “logo Image”, “project name”, “Station ID”, “drawn by” and

“drawing date” information of the drawings that can be filled by automatically

by program. Adding, removing and modification of the sheet templates is possible

through “sheet templates” tab in options window. (Explained in

Error! Reference source not found.

8.1.3

).

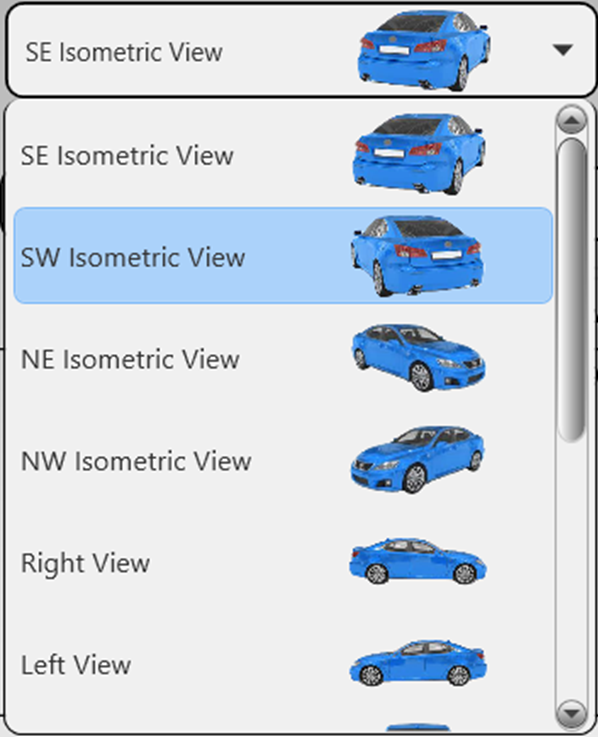

6.3.1.8. ViewPoint Selection

The view point selection combo appears on top right side of the PSC Dialogue box. This combo provides a list of frequently used viewpoints in engineering drafting. A small car image from the corresponding view point is shown for each listed view point. A custom view point option is also given at the end of the list, by choosing of which, the user can create the drawing in any desired view as explained in section 6.3.1.9 .

Figure 6 ‑ 14 View Point Selection Combo

6.3.1.9. Custom Viewpoint

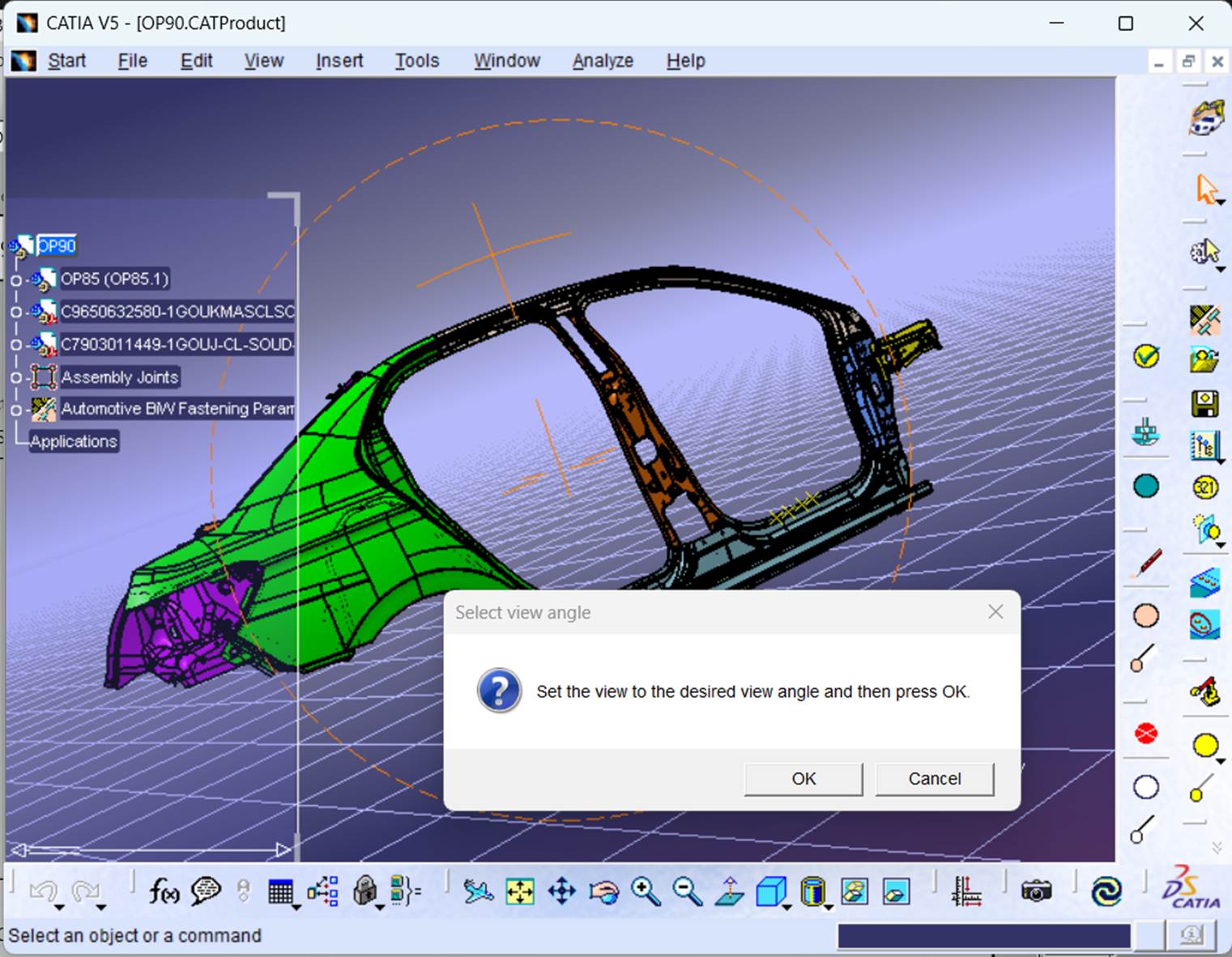

If the custom viewpoint (

![]() )

is selected in the viewpoint selection combo, the program will ask the user for

adjustment of the viewpoint and drawing extents during creation of the drawing.

After, clicking on the “Create drawing” in the PSC dialogue box it might take a

short while for the program to load the component in Catia. The program brings

Catia to the view of the user with a message box stating “Please adjust the

view angle the desired and click OK”. At this moment the user can adjust the

view angle of the model in the desired angle by means of available options in

Catia like

)

is selected in the viewpoint selection combo, the program will ask the user for

adjustment of the viewpoint and drawing extents during creation of the drawing.

After, clicking on the “Create drawing” in the PSC dialogue box it might take a

short while for the program to load the component in Catia. The program brings

Catia to the view of the user with a message box stating “Please adjust the

view angle the desired and click OK”. At this moment the user can adjust the

view angle of the model in the desired angle by means of available options in

Catia like

![]() ,

,

![]() ,

,

![]() ,

mouse gestures, etc. After adjusting the desired angle, the user should click

on “OK” button in the message box. It then takes a while for the program to

generate the drawing.

,

mouse gestures, etc. After adjusting the desired angle, the user should click

on “OK” button in the message box. It then takes a while for the program to

generate the drawing.

Figure

6

‑

15

Drawing adjustment dialogue

window

6.3.1.10. Create Drawing Button

By clicking on this button, the program starts to create the drawing or drawings for the selected process IDs with respect to the selected viewpoint and sheet template. There are more options available in “PS Sheet” tab in options window (See 8.1.4 ) for creation of the drawings. During creation of the drawings the Catia and Excel applications are hidden by the program, however, it is possible to unhide them through corresponding menu items in “Options” menu (See 8.2 and 8.3 ). After creation of the drawings, Catia and Excel application will be visible again. If several drawings are created in a batch drawings creation a window, listing created drawings, will be opened and in case of creation of a single drawing a drawing detail window will be opened.

If partial view check box is checked in the PSC dialog box, the program will ask the user for adjustment of the and drawing extents during creation of the drawing. As explained in section 6.3.2 .

6.3.2. Partial View Creation

If partial view check box is checked in the PSC dialog box, the program will ask the user for adjustment of the drawing extents during creation of the drawing. A partial view drawing focuses on the selected part of the component and only the focused part is depicted in the drawing. A small whole view of the drawing is created on a corner of the drawing in which a rectangle indicates the extents of the selected part of the view. An example of a partial view drawing is shown in Figure 6‑16 .

Figure 6 ‑ 16 An example of a Partial View Drawing

There are two different options for drawing extent adjustment with can be chosen through a pair of radio buttons in the options window (See 8.1.4.3 ). These options include “In Catia” and “In Crop Window” which are explained here.

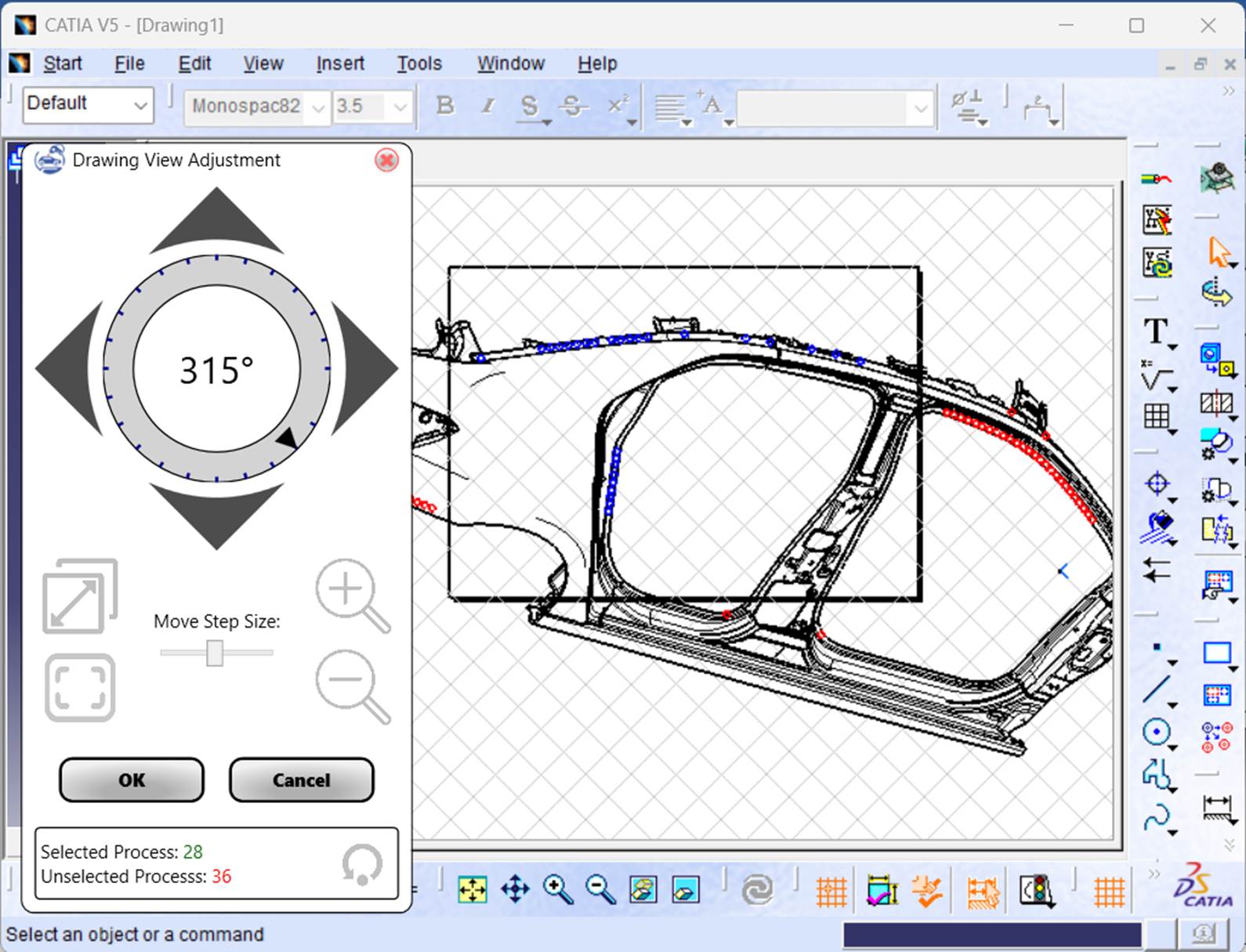

6.3.3.

Partial View Extent

Adjustment in CATIA

If “In Catia” choice is selected for creation of the partial views (In Program Options), after creation of the drawing scheme the drafting window of the Catia appears to the user with the drawing of the whole component model made in the selected view angle. A drawing adjustment dialog window appears on top of the Catia window which provides tools for magnify, minify, move and rotate or fit in page of the drawing etc. as shown in Figure 6‑17 .

Figure

6

‑

17

Drawing Extent adjustment in Catia

The user can adjust the intended extent of the drawings so that the part of the drawing lies inside the boundaries of the drawing sheet (appearing as a black thick rectangle in the Catia drafting window). The adjustment can be done by means of the tools in the extent adjustment dialog window. The selected process definitions for the drawing appear in the drawing as tiny circles. If the process lies inside the boundaries the process is colored blue and in case the process lies out of the boundaries the color turns red. This way the user can consider the inclusion of desired processes in the drawing.

6.3.4.

Partial View Extent

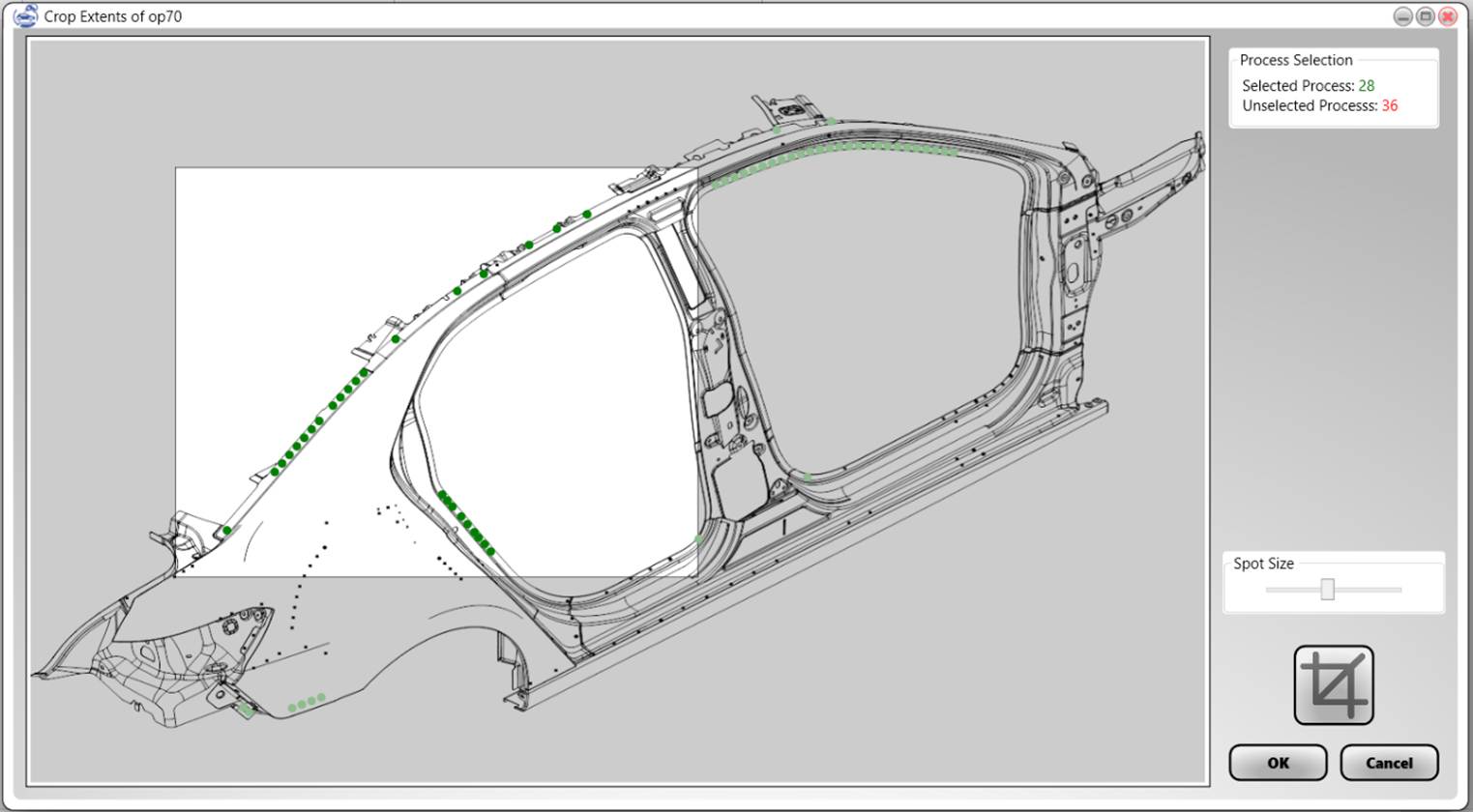

Adjustment in Crop Window

As an alternative way of

adjustment of the extents of the drawing, the program provides a crop window in

which the user can select the desired boundaries of the drawing. After creating

the drawing scheme, the program opens a crop window in which the whole view of

the drawing is shown to the user. The selected processes appear as green solid dots

on the drawing. If moues pointer is kept on each of the process dots, a brief

report of the process information appears on the screen.

The drawing extents can

be selected by clicking on a corner of the perceived view rectangle and

dragging it up to the opposite corner. The selected area will be shown as a

bright rectangle and the outer areas turn darker. Also, the color of processes,

out the selected boundary, turn pale. As shown in

Figure 6‑18

.

Figure

6

‑

18

Extent Adjustment in Crop Window

As shown the statistics

of selected and unselected processes is shown on side bar of the crop window,

as well as a slider for adjustment of size of the process dot marks. A crop

reset Button (

![]() )

allows the user to reset the selected extent button. By clicking on ok the

selected extent is confirmed and the drawing is created accordingly.

)

allows the user to reset the selected extent button. By clicking on ok the

selected extent is confirmed and the drawing is created accordingly.

6.4. Process Sheet Settings

This menu item opens the

process sheet setting options tab in the options window.

(see

8.1.4

)

6.5. Manage Sheet Templates

This menu item opens the

drawing sheet templates tab in the options window.

(see

8.1.3

)

6.6. Manage Standards

The default standard of

Catia BiW Fastenings module is predefined in the

program under name of “GBF_STD” with the default process types as those of

default “GBF_STD” standard of Catia. If the BiW

Fastenings standard in Catia is customized or new standards are defined in

Catia, the equivalent standard can be defined or edited in the BiW-AP to correspond it. More information about Catia BiW Fastening standards can be found in the help documents

of Catia. Definition of custom BiW fastenings in

Catia is not a common practice. So, if your Catia BiW

Fastening is not customized you can skip this reading section.

If your Catia BiW Fastening is customized, it is recommended to follow

the instructions of this section with consultation of the expert persons in

charge of customization of BiW fastenings module of

your Catia. Because this section uses the same parameter names and settings as

those used in BiW fastenings module of Catia.

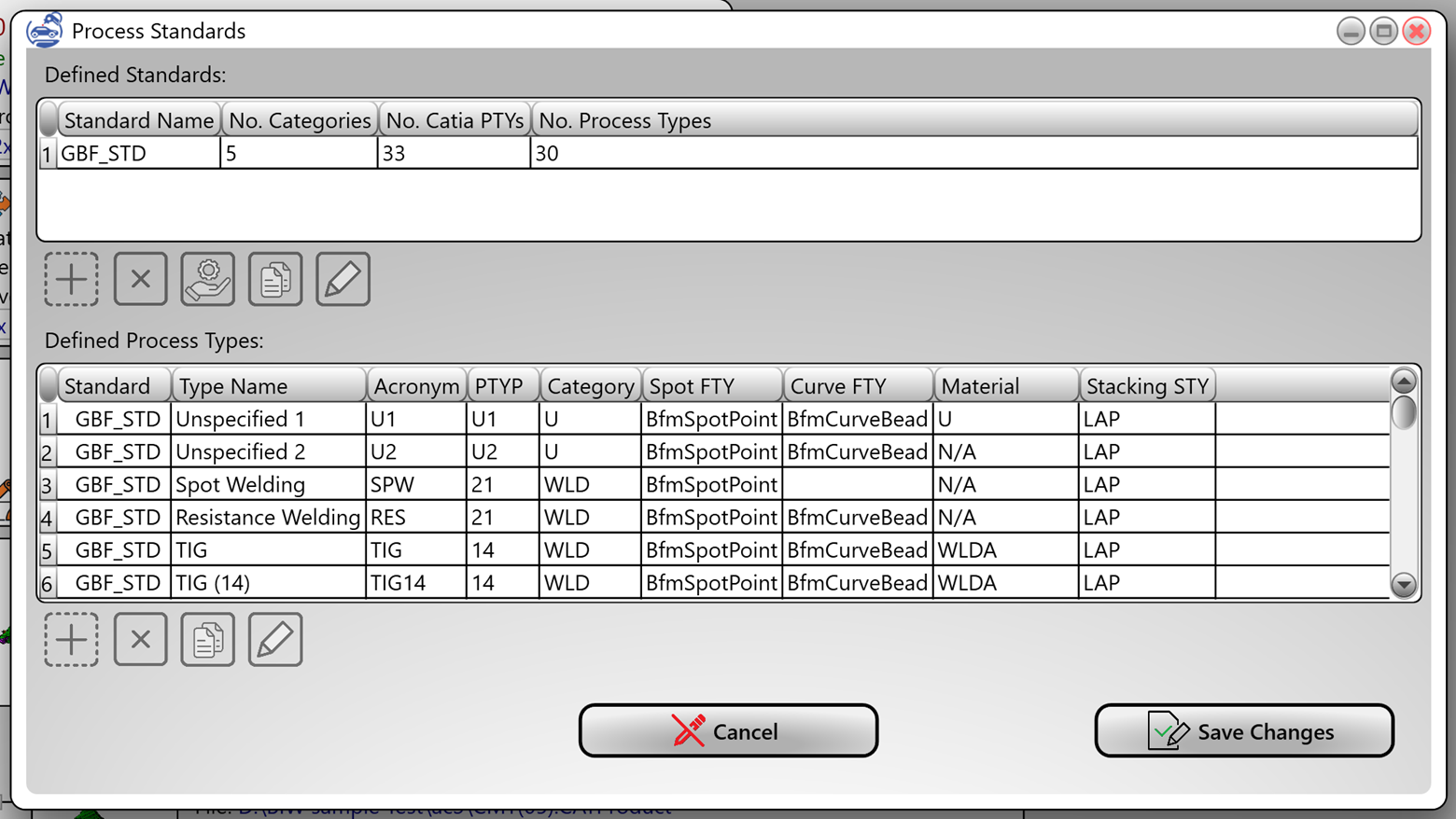

A click on manage

standards menu item opens the standards management window as shown in

Figure 6‑19

.

Figure 6 ‑ 19 Manage Process Standards Window

6.6.1. Defined Standards

A list of defined

standards is shown under defined standards label in the standards management

window.

Icon buttons under this

list i.e.

![]() ,

,

![]() ,

,

![]() ,

,

![]() ,

,

![]() respectively allow adding new standard, deleting

a standard from the list, loading default standard definition, making a

duplicate copy of the selected standard and editing the selected standard.

respectively allow adding new standard, deleting

a standard from the list, loading default standard definition, making a

duplicate copy of the selected standard and editing the selected standard.

6.6.2. Defined Process Types

Accumulative list of

defined process types according to all defined process standards, is shown on

bottom of the window. Icon buttons under this list i.e.

![]() ,

,

![]() ,

,

![]() ,

,

![]() respectively allow adding new process types,

deleting a standard from the list, making a duplicate copy of the selected

process type and editing the selected process type.

respectively allow adding new process types,

deleting a standard from the list, making a duplicate copy of the selected

process type and editing the selected process type.

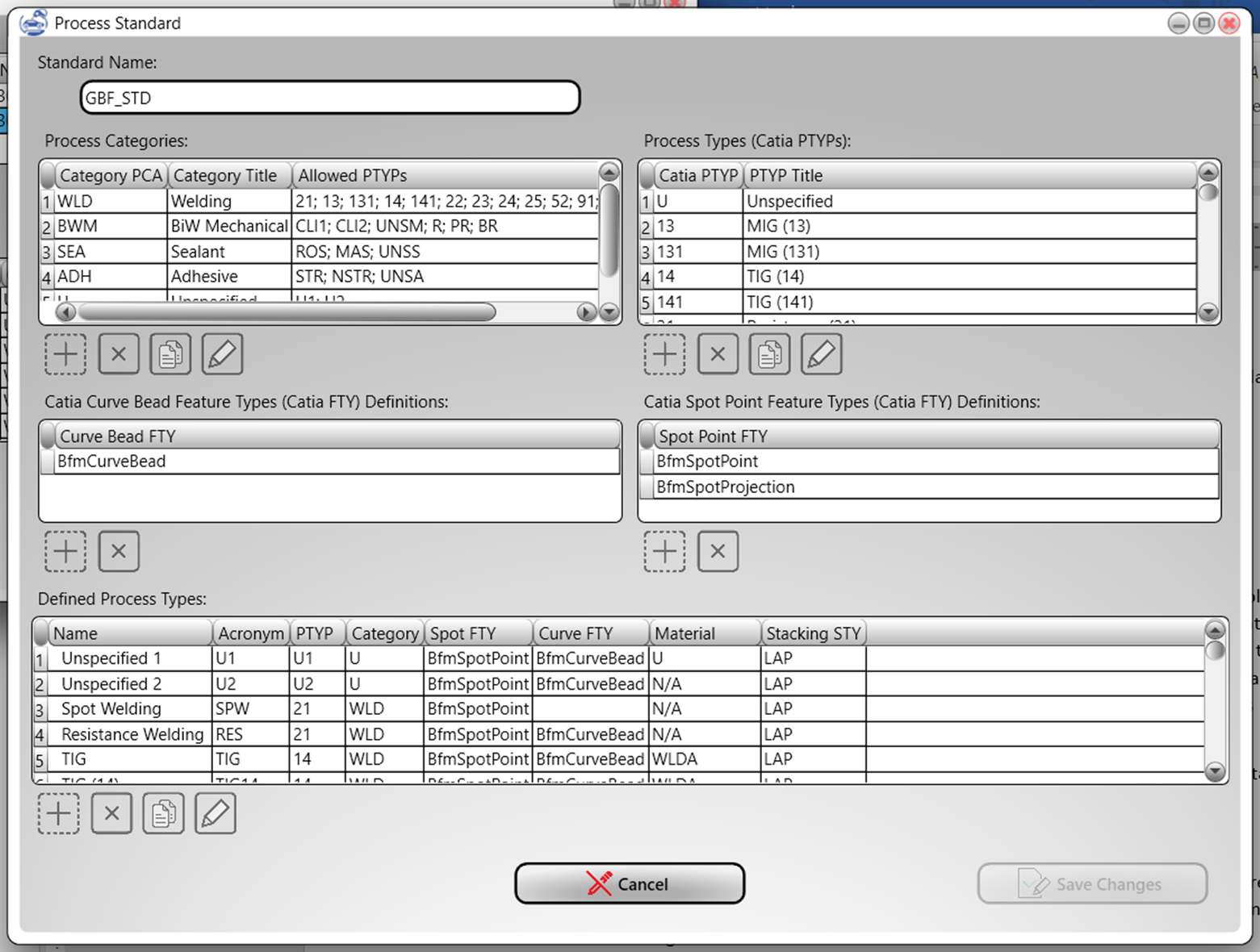

6.6.3. Define and Edit a Standard

A new Standard can be created

by clicking on each of new default or copy standard buttons (i.e.

![]() ,

,

![]() or

or

![]() ) under the defined standards lint in the manage

process standards window. After creation of the new standard, it can be edited

by clicking on the edit button (i.e.

) under the defined standards lint in the manage

process standards window. After creation of the new standard, it can be edited

by clicking on the edit button (i.e.

![]() ). The standard edit

window opens as shown in

Figure 6‑20

. This window allows to define the standard

process type and parameter definitions corresponding to those of customized

standard in Catia.

). The standard edit

window opens as shown in

Figure 6‑20

. This window allows to define the standard

process type and parameter definitions corresponding to those of customized

standard in Catia.

Figure

6

‑

20

Edit Standard Window

6.6.3.1.

Standard Name

The standard name can be

directly edited in the standard name text box on top of the window. It should

be the same as the standard name in your Catia in case you wish to

import/export process definitions between BiW-AP and

Catia. The default standard name in Catia is GBF_STD and it is already

available in BiW-AP as the default standard

definition.

6.6.3.2.

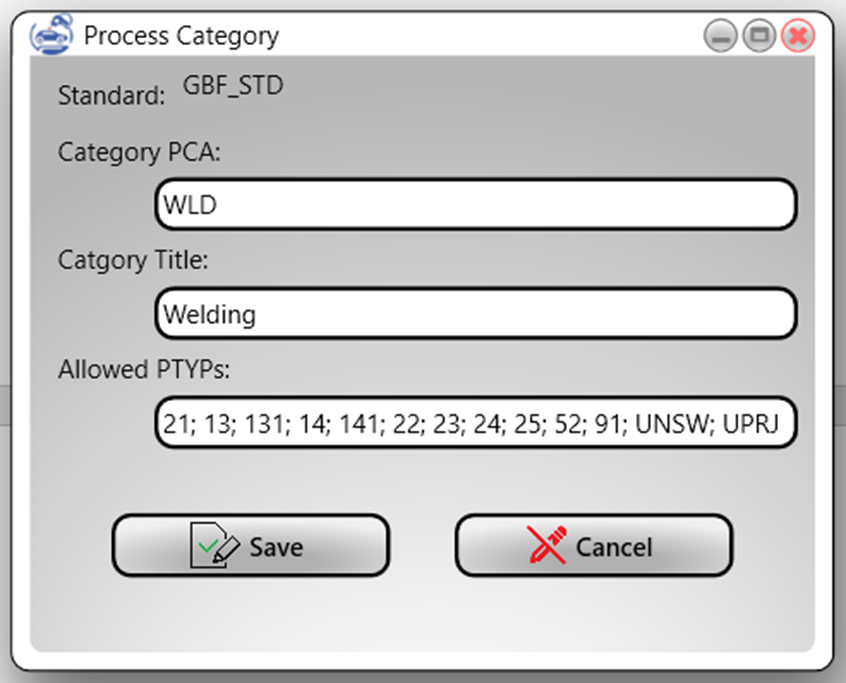

Catia PCA

The process categories,

named PCA in Catia standard definition (Ref. Catia help documents), are defined

in this list. The PCA definitions can be added, deleted, copied or edited by

clicking on the icon buttons under the list. By Clicking on either of the add

or edit buttons, a PCA edit window opens for editing the new or selected PCA as

shown in

Figure 6‑21

.

Figure

6

‑

21

PCA Edit Window

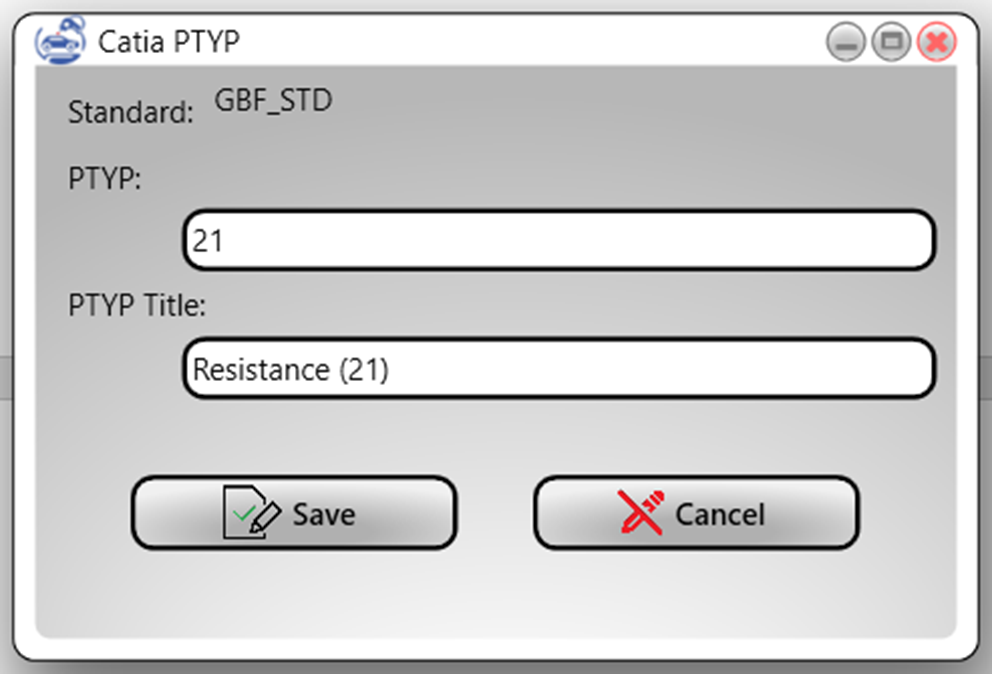

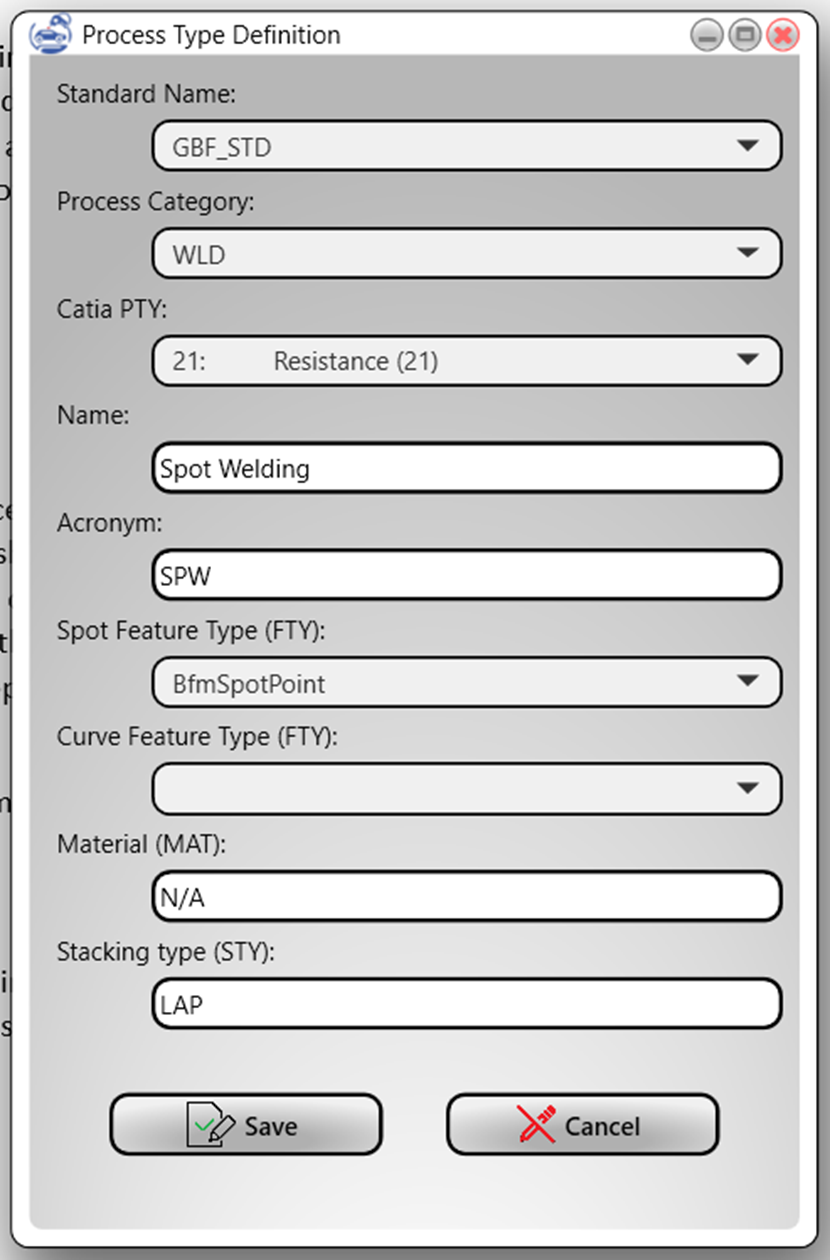

6.6.3.3.

Catia PTYP

The process types, named

PTYP in Catia standard definition (Ref. Catia help documents), are defined in

this list. The PTYP definitions can be added, deleted, copied or edited by

clicking on the icon buttons under the list. By Clicking on either of the add

or edit buttons, a PTYP edit window opens for editing the new or selected PTYP

as shown in

Figure 6‑22

.

Figure

6

‑

22

PTYP Edit Window

6.6.3.4.

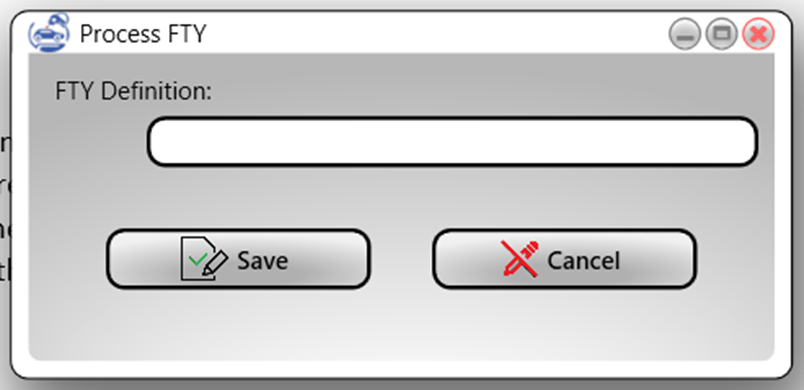

Catia FTY

The feature types, named FTY

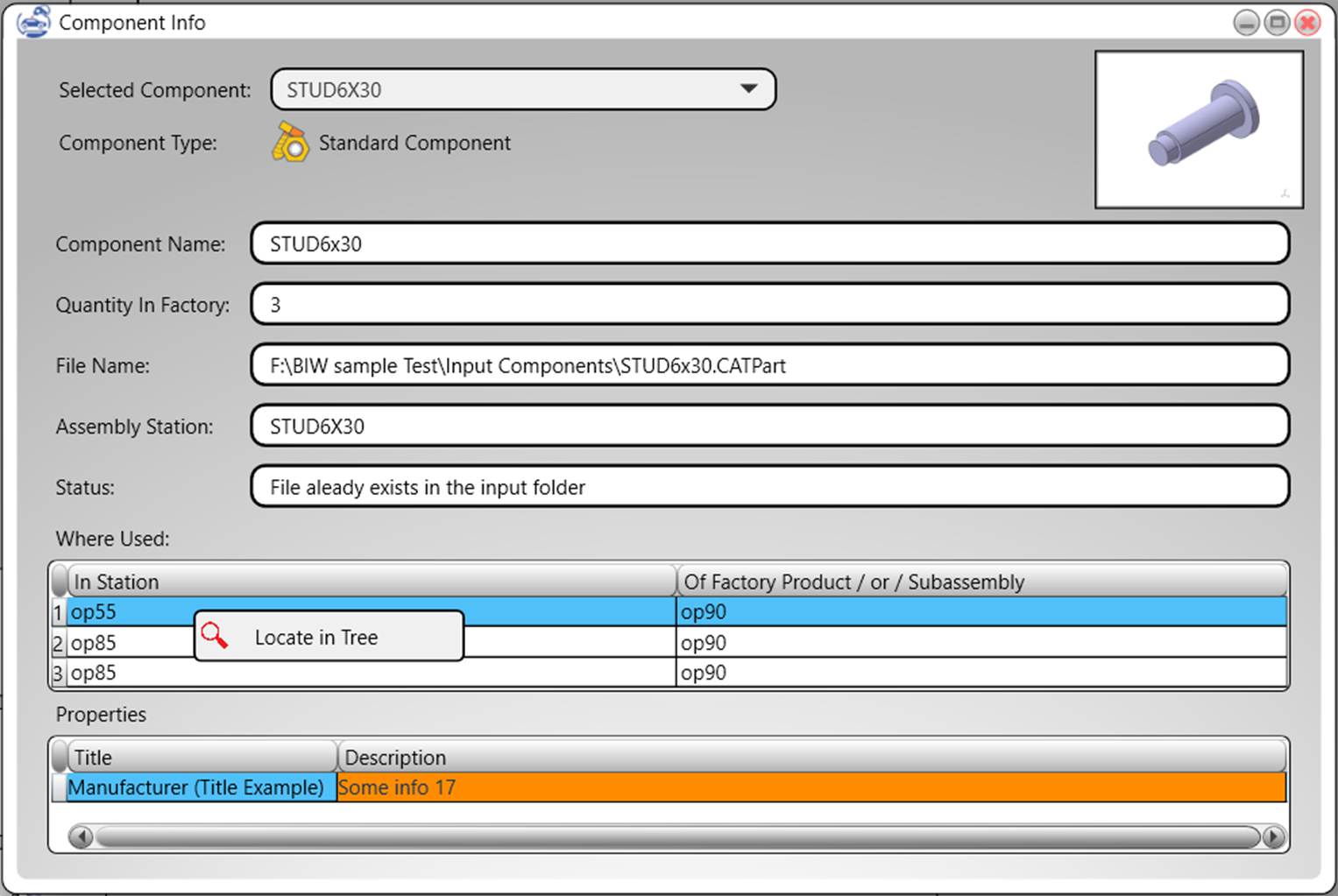

in Catia standard definition (Ref. Catia help documents), are defined in two